Perishable goods might be difficult to transport from the place of production to the customer. Temperature decreases can occasionally be caused by activities including loading, unloading, packaging, and shipping, among others, whilst tilting a vaccination vial might result in significant losses. Consequently, it is essential to keep an eye on deliveries from Point A to Point B. The merchandise may be tracked by the operator from storage through delivery. Product monitoring technology preserves the integrity of the items while saving time and money.

Without a sound plan in place, company owners run the danger of suffering significant financial losses and, more significantly, losing the confidence and integrity of their clients. Instantaneous reporting made possible by real-time monitoring allows one to respond before a product is harmed.

The cold chain was unusual and laborious when there was no real-time monitoring. The first step for suppliers was to identify the defective items and have them discarded. a thorough investigation that might take weeks or months to find the problem. The team would next create protocols to stop or lessen future damage.

Today, suppliers may have complete visibility of their items regardless of location owing to technological advancement, resulting in improved dispatches.

What Is Real-Time Monitoring?

The supply of continually updated data with zero or minimal delay is known as real-time monitoring. Receiving data in real-time gives you the chance to solve issues quickly and identify and foresee patterns.

Consider unusual samples that must be frozen in order to remain viable. One risks losing priceless specimens if the temperature changes alarmingly while in transportation. On the other hand, the samples can be saved if the proper real-time temperature monitoring system is in place. One can always spot the looming warning flags in the data.

Real-time monitoring may now be a component of a network of connected computer devices that gather and share data without the need of human engagement. The internet of things (IoT) is a term used to describe this kind of technology.

The Importance of Pharma Cold Chain Monitoring

1.Monitor the temperature of the product

The operator can follow the product’s progress thanks to the monitoring system. This enables them to act quickly in an emergency and avoid paying for product damage. Pharma items are transported throughout the area, the state, and the nation, so monitoring systems may tell the drivers of different product parameters, allowing them to decide whether to deliver the product safely and avoid a potential temperature decrease.

2.Preserves the quality of the product

All types of pharmaceutical items, including vaccinations, are shipped via cold chain. Operators must treat each product individually since each has unique temperature needs. The vaccinations and other medications become less effective with even a slight temperature fluctuation, making them even riskier to use. On the other hand, a monitoring system provides you with a second-by-second update on the items’ state. Operators are able to manage the items’ temperature and keep their quality in this way.

3.Averts future damage

Even minor shipping annoyances can trigger an alarm from the monitoring system, which gives the operator time to take appropriate action. Without it, there might be product waste, commercial risk, and even potential injury to customers. For instance, a patient’s health would worsen if they received an injection of medication that had not been adequately chilled since it would be poisonous and ineffectual. Such flaws may be avoided by using a monitoring system, which would also shield a business, a product, and consumers from possible harm.

4.Increases process efficiency

You have control over the process when you can inspect the product from the point of origin to the point of use. You can make wise judgments during emergencies and prevent delivery delays, which will make your company dependable, quick, and efficient. When you include a monitoring technology in your cold chain management system, this will be attainable. It will streamline the procedure and greatly improve your company.

Benefits of Real-Time Monitoring

Profitably increase by avoiding product damage. Here’s how to do it:

Immediate Notices: Determine the seriousness of the issue and what may be done to salvage the products. The monitoring system will be notified by even a small temperature change, and it will then send a notification.

Accuracy: Reduce the possibility of human mistake by using independent data collection methods that are quick and dependable.

Customized Indicators: Customizing indications depending on product kinds is feasible at any moment with the correct real-time temperature monitoring system.

Automation: The start, halt, and upload of processes at the sender and destination can all be automated. Improve your supply chain management.

Analytics and Reports: Reports produced automatically by a real-time temperature monitoring system are crucial for studying patterns and developing new policies. This information may be used to forecast future trends and spot problems before they get out of hand.

Location Tracking: Real-time temperature and humidity monitoring sensors, which combine position, temperature, and humidity information in one device, open up new possibilities for tracking the location of assets. A greater service level (proactive intervention) from logistics service providers can lead to less product loss and budget waste. Additionally, they may manage fleets more effectively by using the information at hand.

Data Accessibility: Anyone with a verified account can access information anywhere there is internet connectivity. The day when one needed to manually request temperature data in order to keep current is long gone. Without having to locate data loggers, set up software, or teach staff how to submit information, one can monitor temperature changes across the supply chain using a real-time temperature monitoring system.

Lower the Cost of Administration. Heat maps and insurance claims are two examples of how location and aggregated temperature/humidity data may be utilized to optimize the cold chain and cut costs.

Which Cold Chain Monitoring Technologies Can You Use?

Modern Cold Chain Monitoring Technologies are being used by the pharmaceutical industry to combat product deterioration. ELPRO, a Swiss-based global leader in the sector, is the innovator in developing cutting-edge Cold Chain Monitoring Technologies suitable for the pharmaceutical, life science, biotech, and healthcare sectors.

Temperature Data Loggers

Temperature data loggers are often included in the cold chain shipment in transit and are undoubtedly the most common cold chain temperature tracking solution available today. The following Temperature Data Loggers are the most adaptable in the world by ELPRO.

- Monitors your priceless valuables while in storage or transit

- 100% calibrated temperature sensor with high accuracy

- Easy to use and secure

- Able to work with the liberoMANAGER cold chain database from ELPRO

- Alarms that go off and on

A highly adaptable, multipurpose PDF logger, LIBERO CL may be used to track shipments as well as site and storage conditions. The internal temperature sensor has a 100% sensor calibration and is very accurate. LIBERO CL enables you to design temperature profiles by supporting up to eight temperature alarm zones, MKT, and duration as alert criteria.

for certain goods. Additionally, if the alarming conditions are needed again, you may turn the alarming feature off and back on. When a refrigerator or shipping box needs to be cleaned, for instance, this might be helpful.

Depending on how often the Bluetooth® interface is used, LIBERO CL’s battery life can last up to 3 years and it can store up to 75’500 temperature information. For simple placement on your equipment, you can purchase it with a stainless steel bracket as an alternative. Based on the OK or ALARM state on the display, release items with confidence, and get the PDF report using the

simple USB interface without the need for extra software. You may also use the LIBERO Cx BLE app, which is available for iOS and Android, to download the PDF to your smart device via the logger’s Bluetooth® interface. With this app, you can start or stop the logger without removing it from your equipment or shipment.

- Monitors your priceless valuables while in storage or transit

- 100% calibrated humidity and temperature sensor

- Easy to use and secure

- Able to work with the liberoMANAGER cold chain database from ELPRO

- Alarming both off and on

LIBERO CH is a highly adaptable, multi-purpose PDF-logger for tracking shipments as well as site and storage monitoring conditions. A 100% sensor calibration is included with the internal combination temperature and relative humidity sensor1.

You may construct temperature/humidity profiles for specific items using LIBERO CH, which supports up to eight temperature alarm zones, two humidity thresholds, MKT, and duration as alarm criteria. If alarming conditions are necessary, you may also choose to turn the alarming feature on and off again. When a storage container or transit box has to be cleaned, for instance, this might be helpful.

When using the Bluetooth® interface, LIBERO CH can record up to 75’500 measurement values, including 37’750 values for temperature and humidity, and has a battery life of up to 3 years. For simple placement on your equipment, you can purchase it with a stainless steel bracket as an alternative. Release items with assurance in light of the OK or ALARM status on the

Without extra software, the handy USB interface may be used to display and download the PDF report. Alternatively, you may use the logger’s Bluetooth® interface to use the LIBERO Cx BLE app, which is available for

You may start or stop the logger using iOS and Android without removing it from your equipment or shipment.

- Simple and secure; requires no tools or software

- Swift implementation, including from other parties

- Compatible with the cold chain database liberoMANAGER

- 100% calibrated electronics and sensors

- Complete adherence to industry standards

A PDF Logger called LIBERO CS streamlines the shipping procedure for goods whose stability data are known. The LIBERO CS enables the user to develop temperature profiles for specific items by supporting up to eight alarm levels, MKT, and duration as alert criteria. Apply the proper configuration profile, add the shipment details, and send off the logger without keeping separate loggers on hand. Release items in accordance with the display’s OK or ALARM state, download the PDF report, and transmit it to the sender to liberoMANAGER, ELPRO’s cold chain database, for additional analysis.

- Simple and secure; requires no tools or software

- Swift execution, also by 3 A third party

- Compatible with the cold chain database liberoMANAGER

- 100% calibrated electronics and sensors

- Complete adherence to industry standards

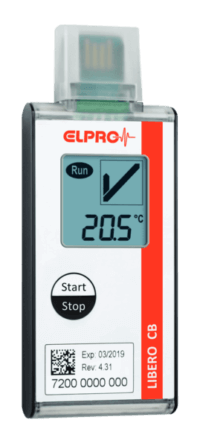

For practically every difficulty involving cold chain monitoring, LIBERO CB is the all-purpose PDF logger. LIBERO CB provides all you need and lets you independently configure these restrictions, whether you need stringent upper and lower alarm limits, alarm on MKT, or time. No need to have a variety of loggers on hand. Simply send the logger off after applying the proper configuration profile and adding shipment information at the time of usage. No hardware is needed, and no software installation is necessary. Read the PDF report and submit it back to the sender or to ELPRO’s cold chain database, liberoMANAGER, for additional analysis.

- Cable-free, installation is simple

- Independent of external power sources and the internet

- Unbroken log of measurement values

- Automatic list of minimum and maximum temperatures

- 100% compliance for clinical sites and pharmacies

The most flexible option for pharmacies, healthcare locations, and laboratories is LIBERO W. There is no need for a difficult installation because it is wireless and battery-powered. You can quickly get up and running by installing the sensor in the refrigerator or other piece of equipment you wish to monitor and turning on the LIBERO W base station. Use a preset device that is prepared to use, or use many reporting settings to tailor the device precisely to your application. The gadget has a reminder function and an integrated USB cord for a secure and regular reading. tranquility for your demanding surroundings.

- Internal temperature sensor directly into dry ice

- Covers all dry ice situations, including those below -80 °C.

- Immediately functioning after being taken out of the dry ice

- Unparalleled precision, completely calibrated, and certified with a trace

- Compatible with the cold chain database liberoMANAGER

With an inbuilt temperature sensor and additional battery life, LIBERO CD is a PDF Logger that can be placed directly into the challenging dry ice environment. You may send dry ice without worrying since the single-use PDF Logger measures and records lowest temperatures occuring in shipments of dry ice as low as -95.0 °C. With support for up to eight alert levels and the option to add shipment-specific information, it enables user-specific programming.

Click here to find out more about Pharma Cold Chain Monitoring and Cold Chain Monitoring Technologies You Can Use today.