A effective immunization campaign depends on the vaccines arriving at their destination safely. They lose their efficacy if exposed to high temperatures over extended periods of time. It can be risky for patients with chronic illnesses to take a compromised dosage. It is essential to use remote monitoring technologies to stop cold chain breakdowns.

Differentiating between a compromised product and a safe one can be difficult. Providers of pharmaceuticals and vaccines need to take precautions to guarantee that their goods are preserved properly.

The process that keeps medications at a low temperature for use, transportation, and storage is called the “cold chain.” The cold chain can fail in a number of ways. Logistic providers employ remote monitoring technologies to prevent problems in the cold chain. Alerts are sent out when temperatures drop below the suggested levels and jeopardize medication.

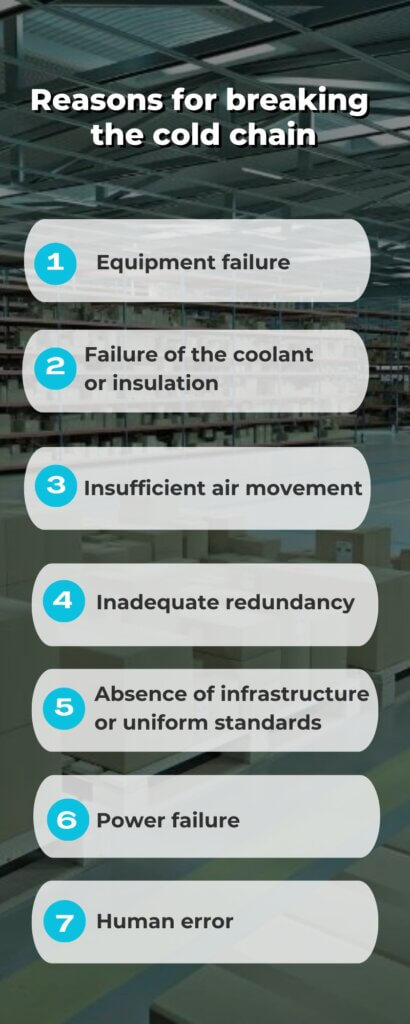

Reasons for breaking the cold chain

Equipment failure

It is crucial to be aware of equipment failures or faults in order to safeguard medical supplies. Refrigerators keep medical supplies from spoiling by maintaining a steady temperature. Expensive repairs are reduced by preventative maintenance. What happens, though, if a problem arises outside of the planned maintenance window?

Check the temperature to safeguard the inventory sensors and remote monitoring systems. The monitoring system looks for equipment failure, including variations in power and temperature.

These devices have the ability to record data. Providers of Vaccines for Children (VFC) are required to install these sensors. Any facility that keeps pharmaceuticals frozen or refrigerated should use them. To demonstrate compliance, they keep a record of all temperature data that is available for download at any time. With the use of this data, environmental trends can be identified and issues can be identified before they become serious.

Failure of the coolant or insulation

Passive-cooling temperature-controlled containers rely on a coolant component within the package. The parcels are both airtight and insulated. The packing isn’t perfect, though. Mishandling the package could lead to damage that compromises the coolant and insulation.

Insufficient air movement

Proper air circulation is necessary for optimal cooling in temperature-controlled settings that rely on active cooling. In cold chains, clogged vents or hotspots in temperature-controlled zones are serious issues. Usually, there is little time to undo the harm by the time it is discovered.

Inadequate redundancy

Delays and breakdowns are inevitable. These occurrences are somewhat accommodated by cold chains. However, backup or redundancy mechanisms have to be in place.

Absence of infrastructure or uniform standards

Disparities in cold chain norms, infrastructure, and technology include:

- Insufficient temperature-controlled storage facilities

- Inconsistent cooling requirements amongst intermediate storage establishments.

Those in charge of international operations find it challenging to ensure end-to-end integrity.

Power failure

Power disruptions. Mainline power is not always dependable in certain places. Systems that are vulnerable include trucks and other forms of transportation without redundant backups. Keep a steady power source in place to guarantee that medications and vaccinations are stored properly. Medical supplies may be lost as a result of a disruption in the cold chain brought on by power outages.

Systems for remote monitoring alert users as soon as the power status changes. An alarm will be sent by phone, email, or text message to the relevant personnel. A battery backup system will also offer eight hours of nonstop monitoring. Systems for remote monitoring provide ample opportunity to resolve issues before inventory is jeopardized.

Human error

Another major issue contributing to the breakdown of the cold chain is human error. When freezers and refrigerators were left unattended, human error happened. Human mistake occurs when a door is left open or when staff members forget to record temperatures.

Systems for remote monitoring reduce the possibility of human error. It guarantees that the temperature stays within the advised parameters. Additionally, when temperatures fluctuate, activate corrective action. It sounds an alert when the refrigerator door is left open or the temperature changes. If the facility is left unattended for a lengthy period of time, these characteristics come in handy.

Pharmaceuticals and vaccines are costly and occasionally difficult to replace. Systems for remote monitoring operate around-the-clock and offer an audit trail to demonstrate compliance.

Cold Chain Risk in Delivery and Distribution

There are more considerations for mobile cold storage than there are for stationary temperature-controlled facilities. Studies conducted in distant places increase the danger of equipment malfunctions and packaging failures, as well as make it more difficult to rescue stranded goods.

Theft and Pilfering

Worldwide supply chains continue to struggle with cargo theft. Whether it’s routine theft and cargo hijacking. Nowadays, cargo pirates consider cold chain vehicles to be valuable targets.

Cold chain management risks and preventing failures in the cold chain

Cold chains continue to break and expose products to risk even with precautions taken to reduce it.

International community businesses are standardizing dependable cold chains that ensure the quality of their products. The goods must be safe to eat and in acceptable condition for delivery, wherever they may be going.

The harm extends beyond the company’s earnings base. It also affects the guarantee of healthcare and food security on a worldwide scale.

A third or more of the world’s food supply spoils annually as a result of insufficient temperature control methods used during transportation. It has an impact on global medical treatments as well as food supplies’ accessibility.

Knowing the biggest threats to their cold chains and how to mitigate them is crucial.

Preventing Cold Chain Failures

Even with the most attentive deterrents on the part of the organization, cold chain interruptions are inevitable. It is feasible to achieve 100% cold chain reliability. It is difficult to balance cold chain risk management expenses in order to cut costs, though. However, supply chain experts now benefit from something their forebears did not: the Internet of Things. IoT aided cold chain management by combining low-cost sensors with real-time shipment tracking.

An effective end-to-end IoT cold chain monitoring system provides shipping managers and quality control staff with the tools they need to guarantee the dependability of the cold chain:

1.) Real-time Data Sensing

It is useful information to know when there is a temperature surge and which cargo may be impacted.

The use of internal temperature sensors in conjunction with USB and Bluetooth® connectivity in real-time monitoring systems and PDF loggers is essential for preventing cold chain accidents. They support the integrity of the cold chain in the following ways:

- Monitoring Temperature: These loggers and systems continuously monitor the temperatures within storage spaces and shipping containers. Their integrated sensors allow them to precisely track variations in temperature, guaranteeing that fragile items are kept within the proper temperature range throughout.

- Real Time Warning and Alert: These monitoring systems are equipped with alert functions that enable them to quickly notify relevant parties when temperature variations take place. The system notifies users via email, SMS, or push notifications when there is a spike or dip that goes above certain thresholds, allowing them to take immediate action to stop possible issues before they arise.

- Documenting Data for Clarity: PDF loggers with USB and Bluetooth® connectivity make it simple to obtain temperature data. Users can readily retrieve the complete data in PDF format, which offer a comprehensive record of the temperature conditions during storage or travel. This documentation is essential for quality assurance, compliance audits, and troubleshooting in the event that a cold chain malfunctions.

- Remote monitoring is made possible by Bluetooth® and USB interfaces, which make it simple to connect PCs, data management systems, and mobile devices. This suggests that users can adjust device settings and monitor temperature patterns even while they’re not physically there, ensuring real-time monitoring and analysis.

- Preserving Quality and Compliance: These systems provide accurate data tracking and maintain consistent temperature settings, which enhance the safety and quality of perishable commodities. By guaranteeing adherence to regulatory requirements including food safety laws and Good Distribution Practice (GDP) guidelines, they lower compliance risks along the road.

- Enabling Proactive Decision-Making: Stakeholders may optimize cold chain operations and foresee potential issues by having access to historical data and real-time temperature adjustments. Prompt remedial action, including reconfiguring configurations, rerouting shipments, or replacing contaminated commodities, is made possible by early temperature change detection

2.) Interpret the Data

Aggregated data is another benefit of continuous monitoring. Practical logistics data is a source of timely, actionable intelligence that can be predicted.

The following variables are used to suggest more efficient routes:

- Delivery window

- congestion on the routes

- Potential alterations

- Fuel usage

- The amount of coolant left

- Using these is more beneficial than making drastic, risky procedural adjustments.

Real-time monitoring would alert in cases of delayed shipments so that appropriate action could be taken. Consequently, sending out a recovery or refit team to fix the problem.

Compared to overcompensating for cold chain risk mitigation strategies, intervention costs are lower. It also permits a more dependable and leaner cold chain.

When it comes to assigning important tasks to the response center, global logistics operations make sense. Large-scale global logistics operations are increasingly adopting outsourced logistics control towers.

There is no way to lower the risk associated with cold chain logistics by doubling up on preventive measures. Reliable data collection, continuous connectivity, and sophisticated analytics are necessary for decision making. for a whole set. solution for monitoring the cold chain.

Today, keeping vaccines cold chain refrigerated is the largest difficulty facing pharmaceutical businesses. A common misperception among medical professionals is that vaccine storage should be kept as cold as possible. resulting in the loss of funds and time used to carry out initiatives for revaccination.

Sadly, stringent laws requiring vaccination temperature monitoring are not required by US agencies. For this reason, parties involved ought to be made aware of the effects of temperature fluctuations. Plans for efficient monitoring along the cold chain can then be implemented.

Cold Chain Packing & Logistics offer a versatile solution for managing temperatures, effectively preventing Cold Chain Failures. Reach out to us today to learn more and safeguard your cold chain operations.