Explore the cutting-edge Cold Chain Storage Technologies of today, ensuring the preservation of temperature-sensitive products. From advanced refrigeration systems to innovative monitoring solutions, discover the key technologies shaping the future of cold chain logistics

The cold chain is a silent but vital player in the enormous world of international trade. However, what is cold chain storage really, and why does it hold such importance globally?

Fundamentally, cold chain storage involves more than just maintaining a low temperature. The processes of manufacturing, storage, and distribution are all coordinated. This guarantees that goods that are sensitive to temperature maintain their effectiveness and quality during their journey from the manufacturer to the customer.

Consider the following scenarios: a family in Dubai indulging in fresh mangoes from India, or a hospital in Africa dispensing a vaccination made in Germany—both are excellent illustrations of how the cold chain enhances lives and ties the world together.

Cold Chain Storage Technologies: Global Standards

Based on the documented worldwide inequalities, there is a great deal of diversity in cold chain norms and procedures. When we look at the developed world, we see that they depend on highly built infrastructure and strict laws. On the other hand, many emerging nations confront challenges including erratic power supply, outdated machinery, and a dearth of specialized skills.

International organizations striving to overcome these discrepancies in quality include the International Institute of Refrigeration (IIR) and the World Health Organization (WHO). The goal? to guarantee that, no matter where their trip starts or finishes, perishable items receive the attention they require.

Innovation in Cold Chain Meets Human Touch

Ultimately, the key to success is to become an expert in cold chain technology through human interaction. Cold chain personnel may readily verify product integrity and handle cold freight remotely by utilizing sensors, IoT devices, and real-time tracking systems to monitor conditions.

However, machines cannot fulfill this duty on their own. The human touch is still invaluable since it is marked by knowledge, devotion, and adherence to procedures. Frequent training guarantees that everyone, from the technician to the truck driver, is capable of managing possible difficulties. This is similar to safety exercises in other industries.

Cold Chain Storage Facilities

The capacity to move temperature-sensitive commodities across long distances without sacrificing their quality is nothing short of a logistical marvel in today’s interconnected global economy. The cold chain, a sequence of distribution and storage operations that keep a product at the proper temperature from point of manufacture to point of consumption, is the central component of this system. However, what are these storage facilities really, and how do they operate?

When it comes to the cold chain and storage, there are a lot of various approaches. You may get a sense of the most common choices that the supply chain provides to all cold chain stakeholders with this brief overview:

Cooling Systems: Goods, particularly food items, must be cooled to the proper storage temperature at the very start of the cold chain. This is where the use of cooling systems is necessary. These are not your typical refrigerators; rather, they are expansive establishments that can manage enormous volumes of merchandise. By doing this, they essentially ensure that goods are at the proper temperature before being transported or kept in storage for lengthy periods of time.

Cold storage warehouses: These warehouses, which can range in size from a single temperature-controlled room to enormous complexes, can hold items for long periods of time. These facilities are the foundation of the cold chain, whether it be a shipment of exotic fruits that need to be delivered to a far-off market or a batch of vaccinations that need to be distributed (learn more about cold chain warehouse management).

Refrigerated trucks and railcars: After goods are removed from the warehouse, they must be delivered to a retail location, a pharmacy, or the customers directly. Here’s where refrigerated trucks and railcars come into play: outfitted with cutting-edge cooling systems, they ensure that chilled goods travels at the perfect temperature.

Reefers: which stand for refrigerated containers, are used to ship commodities across the ocean. Reefers are outfitted with cutting-edge equipment to guarantee constant temperature and humidity levels due to the prolonged sea cruise.

Distribution and Cold Processing Centers: These establishments may handle the last stages of product processing before they are delivered to customers. This location might be used to clean, fillet, and package a cargo of fish, for example. To preserve the items’ freshness and quality at this point, processing them in a temperature-controlled facility is essential.

Blast freezers: These are the preferred choice for goods that must be frozen rapidly. They have the power to quickly lower a product’s temperature and preserve its freshness, which is important for some marine products because even a small delay might lower quality.

Pharmaceutical Grade Cold Storage: Specialized cold storage facilities are now necessary due to the growing significance of biologics in contemporary medicine. These facilities are designed with redundant systems to guarantee that there is no possibility of failure and frequently have to sustain extremely low temperatures.

The cold chain is not a one-size-fits-all solution, as you have seen with the many forms of storage. Its complexities change according to local demands, the state of the economy, and the particular specifications of the items in issue.

Cold Chain Storage Technologies

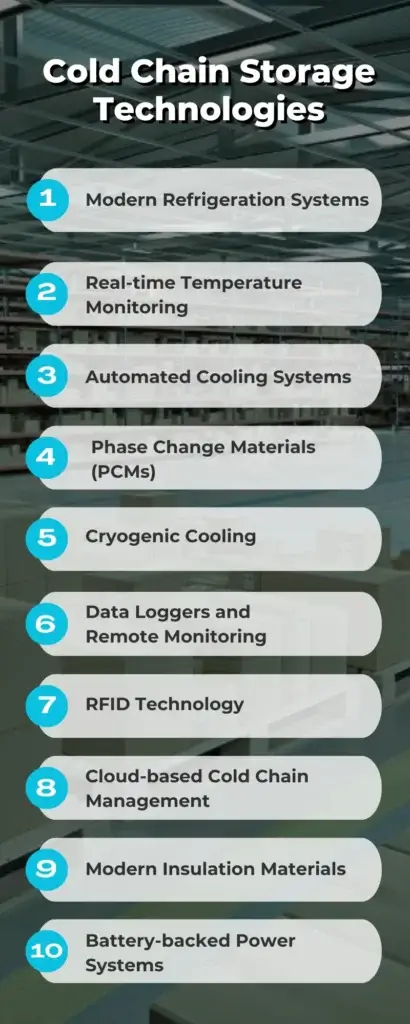

The cold chain is a very delicate movement in the intricate choreography of global logistics. For perishable commodities, such as food or medications, it is critical to be able to maintain and keep an eye on particular temperature ranges. To preserve and track temperature, we compiled the following list of cold chain storage technologies:

Modern Refrigeration Systems: The days of crude cooling are long gone. Variable frequency drives are employed in today’s refrigeration systems, particularly in large-scale warehouses, to enable the adjustment of cooling according to the needs of the goods.

Real-time Temperature Monitoring: Many contemporary cold chain storage technologies includes sensors that can record and display temperature data in real time. The ability to transmit data to centralized systems enables prompt action in the event that temperatures depart from the intended range. Study up on cold chain tracking.

Automated Cooling Systems: Cold chain storage has seen a notable increase in automation. The items being kept, variations in the outside temperature, and other factors may now be used by systems to automatically modify the cooling conditions. This minimizes mistakes by reducing human interaction and ensures constant temperatures.

Materials known as phase change materials (PCMs): are substances that, while undergoing phase transitions like melting or freezing, may absorb or release thermal energy. They are employed in cold chain packing, particularly for medicines, and they maintain the intended temperature range of the goods even while in transportation.

Cryogenic Cooling: Cryogenic cooling is used for products that need to be kept at extremely low temperatures, such some medications. The temperature of liquid nitrogen, carbon dioxide, and other materials can drop as low as -150°C.

Data Loggers and Remote Monitoring: For items in transportation, data loggers—small devices that track temperature over time—are essential. When combined with remote monitoring tools, stakeholders have global access to this data in real time. Data loggers ensure that items have been kept within the necessary temperature range by providing a complete temperature record after the voyage.

RFID Technology: Temperature sensors and Radio Frequency Identification (RFID) tags work together to offer two benefits. They make sure that things are always in the correct place at the proper temperature by tracking not just the product’s location but also its temperature. Learn more about tracking cold chains here.

Cloud-based Cold Chain Management: Cold chain management has advanced significantly with the introduction of cloud computing. Through cloud-based solutions, stakeholders may monitor storage facilities, obtain temperature data, and even remotely modify some settings.

Modern Insulation Materials: There have been major breakthroughs in the insulation used in cold chain storage and transportation. Better insulation is known to be found in materials like aerogels and vacuum-insulated panels.

Battery-backed Power Systems: For cold chain storage, power disruptions can be disastrous. Battery-backed power systems are common in modern buildings, guaranteeing that cooling will continue even in the case of a power outage.

Cold Chain Storage Technologies: Summary

Diverse Technologies: There is no one-size-fits-all approach to cold chain storage. The technique varies according to the product’s unique temperature requirements, ranging from blast freezers to chilled containers.

Real-time Monitoring: To guarantee that items are kept in ideal conditions, contemporary cold chain systems place a high priority on real-time temperature and humidity monitoring. IoT devices and sophisticated sensors are essential to this.

Sustainability Issues: Although cold chain storage is necessary to maintain product quality, its effects on the environment must also be taken into consideration. In an effort to lessen its carbon impact, the sector is moving toward efficient cooling systems and renewable energy sources.

Being ready: System malfunctions and power outages are possible threats. Nonetheless, facilities are now more prepared than ever to address these difficulties thanks to backup power systems and real-time notifications.

Recall that the need for cold chain storage systems will only grow in significance as the world’s demand for perishable commodities rises.

Are you looking for a reliable delivery service for your perishable items that offers cold chain storage technologies? Reach out to Cold Chain Packing & Logistics.

Cold Chain Packing & Logistics makes use of Peli BioThermal, which provides the world’s life sciences sector with the broadest array of temperature-controlled, thermally-protected packaging and service solutions. Our cutting-edge, patented technology and advisory services guarantee product quality, minimize excursion rates, lower packing expenses, and raise total cost of ownership across your supply chain.