Article’s Summary

- Advanced insulation materials: VIPs, aerogels, PCMs revolutionize packaging.

- Cooling technologies: gel packs, dry ice, eutectic plates, electric systems.

- Monitoring technology: wireless sensors, IoT solutions, data loggers.

- Sustainable packaging: biodegradable materials, recyclable packaging.

- Importance of latest packaging: preserve product quality, meet compliance, enhance efficiency, embrace sustainability.

Temperature-controlled packaging plays a critical role in the cold chain logistics industry, ensuring the safe transportation of temperature-sensitive products such as pharmaceuticals, biologics, perishable foods, and chemicals. Maintaining the integrity of these products throughout their journey is paramount to preserve their efficacy and quality. In this article, we will explore the latest advancements in temperature-controlled packaging, including insulation materials, cooling technologies, monitoring systems, and sustainable packaging solutions. These innovations are designed to enhance the efficiency, reliability, and sustainability of cold chain operations. Let’s delve into the details and discover how these cutting-edge technologies are revolutionizing the industry.

Exploring the Latest Temperature-Controlled Packaging

Advanced Insulation Materials

When it comes to temperature-controlled packaging, efficient insulation plays a vital role in maintaining the desired temperature inside. While traditional insulation materials like expanded polystyrene (EPS) and polyurethane (PU) foam have been widely used, recent advancements in insulation technologies have brought forth new options that offer enhanced performance and efficiency. Let’s delve into these advanced insulation materials that are revolutionizing the field of cold chain packaging.

a. Vacuum Insulation Panels (VIPs)

When it comes to achieving superior thermal performance, VIPs have emerged as a game-changer. These panels employ a vacuum-sealed core that minimizes heat transfer. By creating a vacuum within the panel, thermal conductivity is significantly reduced, resulting in exceptional insulation capabilities. VIPs outperform traditional materials, allowing for thinner insulation layers, reducing overall packaging size, and even cutting down on weight. They are particularly beneficial in scenarios where space is limited or weight reduction is a priority. Know more about Vacuum Insulation Panels (VIPs):

b. Aerogels

With their remarkable combination of low density and high insulating properties, aerogels have become an exciting choice in the world of insulation materials. These materials consist of highly porous structures composed of interconnected nanoparticles or nanostructured solids. Thanks to their unique nanostructure, aerogels exhibit extremely low thermal conductivity, making them ideal for applications that demand high-performance insulation. By providing excellent protection against heat transfer, aerogels minimize temperature fluctuations within the packaging, ensuring optimal temperature control during transit. Despite their lightweight nature, they offer reliable thermal integrity throughout the journey.

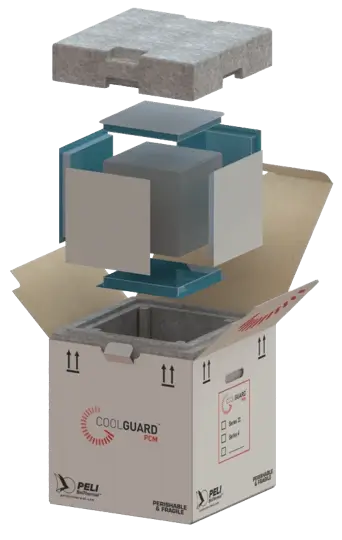

c. Phase Change Materials (PCMs)

Another innovative approach to temperature control is the use of phase change materials (PCMs). These materials have the ability to absorb and release thermal energy as they undergo a phase transition. By changing their state from solid to liquid (and vice versa) at specific temperatures, PCMs actively manage temperature fluctuations within the packaging. This property ensures a stable internal temperature, thereby safeguarding the integrity of temperature-sensitive products. PCMs are commonly incorporated into cool packs or ice packs, where they absorb excess heat and release it when temperatures fall below the desired range.

By embracing these advanced insulation materials, businesses can elevate the thermal performance of their packaging and optimize temperature control during transportation. However, selecting the most suitable material requires careful consideration of various factors such as temperature requirements, duration of transportation, packaging size and weight limitations, and the characteristics of the products being transported.

In fact, combining different insulation materials can further enhance thermal performance and temperature control. For instance, a combination of Vacuum Insulation Panels (VIPs) and Phase Change Materials (PCMs) offers a powerful solution for maintaining consistent temperatures during longer transportation periods. The VIPs minimize heat transfer, while the PCMs absorb and release thermal energy, ensuring a stable temperature environment within the packaging.

Cooling Technologies

When it comes to temperature-controlled packaging for cold chain operations, a range of solutions is available to ensure the preservation and integrity of temperature-sensitive products. Let’s explore some of the latest options and advancements in cooling and temperature control methods:

a. Gel Packs and Coolants

Gel packs and coolants have long been used in short-duration shipments to maintain the desired temperature. These packs, either reusable or disposable, are pre-frozen and placed within the packaging. They work by absorbing heat, thereby helping to regulate the temperature inside. Advancements in gel pack technology have introduced the incorporation of phase change materials (PCMs), which extend the cooling duration and provide more reliable temperature control.

b. Dry Ice

Dry ice, the solid form of carbon dioxide, is a commonly employed solution for long-haul shipments. It offers extremely low temperatures and sublimates without leaving any residue. However, it’s important to handle dry ice with care and ensure proper ventilation due to the potential buildup of carbon dioxide gas. The use of dry ice requires close attention to safety protocols and guidelines.

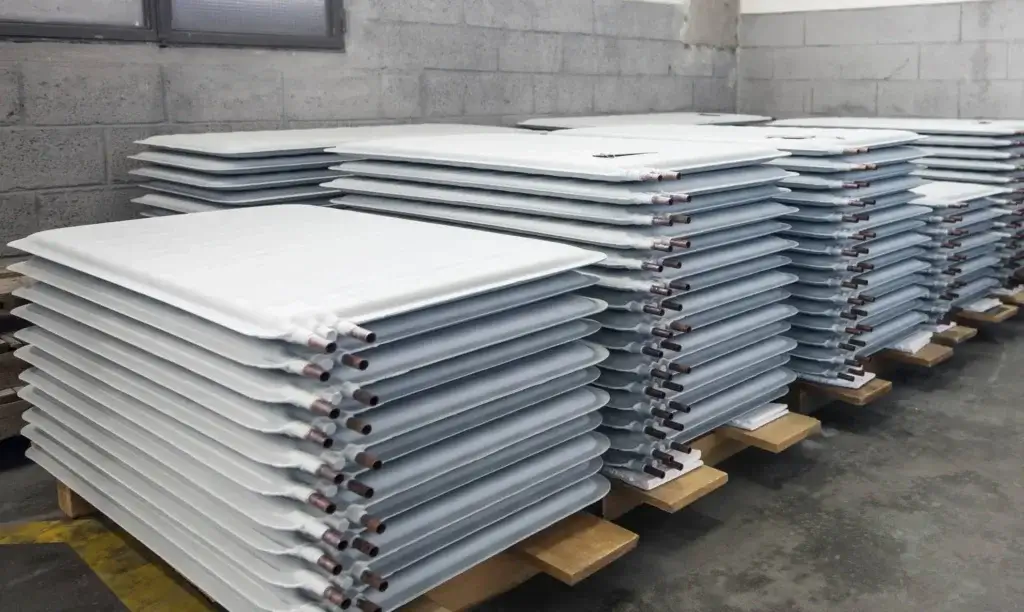

c. Eutectic Plates

Eutectic plates are carefully crafted to keep temperatures consistently stable for extended durations. These plates are chilled beforehand and can be inserted into temperature-controlled packaging to precisely regulate and maintain the ideal temperature throughout the entire journey. What’s truly remarkable about eutectic plates is their reusability and effortless rechargeability, which makes them a practical, cost-effective, and efficient solution for cold chain operations. Consequently, they offer a reliable option for ensuring that products remain in optimal condition throughout the shipping process.

d. Electric and Battery-Powered Cooling Systems

Electric and battery-powered cooling systems excel at providing meticulous temperature control throughout transportation. These systems utilize a range of technologies, including compressors, fans, or thermoelectric cooling, to effectively maintain the desired temperature range. With their reliable and customizable cooling capabilities, they enable precise temperature management. What’s even more impressive is that some advanced systems offer remote monitoring and control, granting real-time data and alerts. This feature enhances both the efficiency and transparency of cold chain operations, ensuring optimal conditions for the transported goods.

The recent progress in temperature-controlled packaging presents a wide range of options tailored to various transportation needs and durations. Choosing the right solution entails considering factors like product sensitivity, transportation distance, duration, and the desired temperature range. It is of utmost importance to carefully assess these aspects and thoroughly evaluate the unique requirements of each shipment in order to determine the most suitable cooling method. By doing so, one can ensure the safe and effective transport of goods while maintaining their quality and integrity.

When it comes to cold chain operations, the significance of reliable monitoring and data logging systems cannot be overstated. These systems play a vital role in safeguarding the integrity and quality of temperature-sensitive products. By offering real-time visibility into temperature conditions, they enable us to promptly detect any deviations, track product integrity, and ensure compliance with regulatory standards. Now, let’s explore some of the exciting recent advancements in monitoring technology:

Monitoring Technology

a. Wireless Temperature Sensors

Wireless temperature sensors have revolutionized cold chain monitoring. These compact sensors can be placed within the packaging to continuously monitor temperature conditions. By wirelessly transmitting data to a centralized monitoring system, they enable real-time alerts and remote access to temperature data. This ensures prompt action can be taken in case of any temperature excursions, preventing potential damage to the products. Learn more about the different temperature sensor with pdf logger.

b. IoT-enabled Solutions

Thanks to the Internet of Things (IoT), we’re experiencing a groundbreaking transformation in cold chain monitoring. By leveraging interconnected temperature sensors, gateways, and cloud-based platforms, IoT-powered solutions revolutionize data transmission and analysis. This remarkable technology enables real-time data analysis, predictive analytics, and remote temperature monitoring, granting businesses unparalleled visibility and valuable insights into their supply chain. With IoT at their disposal, stakeholders can make informed decisions, optimize routes, and proactively tackle temperature-related challenges head-on, ensuring the utmost product integrity and customer satisfaction.

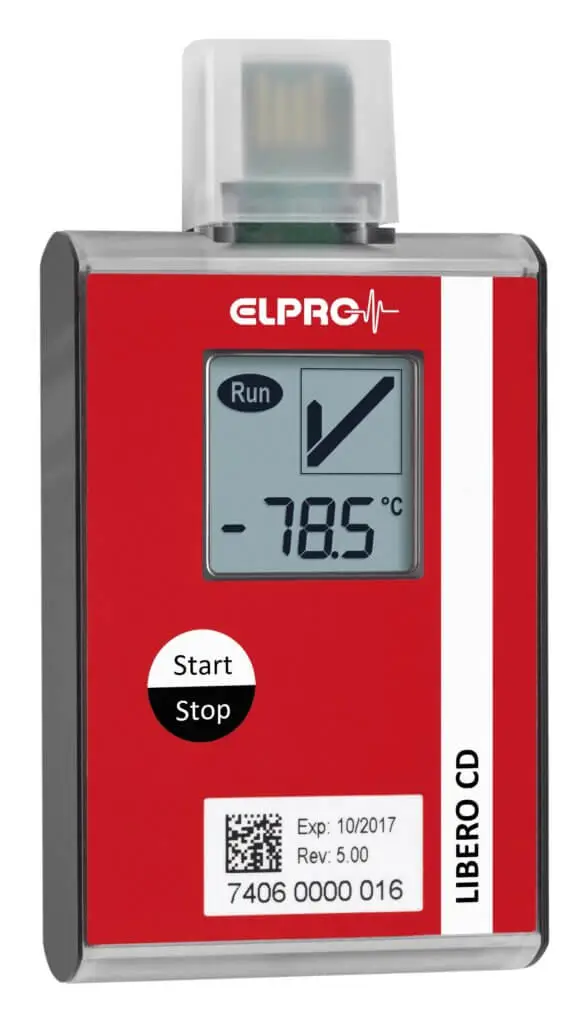

c. Data Loggers

Data loggers have long been a trusted tool for temperature monitoring and documentation during transportation. These devices record temperature data at regular intervals and are widely used across various industries. Advanced data loggers offer extended battery life, high data storage capacity, and the capability to generate comprehensive reports. They serve as a reliable source of historical temperature information, facilitating quality control, auditing, and compliance assessments.

Implementing these advanced monitoring and data logging systems in cold chain operations provides numerous benefits. They enhance supply chain visibility, improve operational efficiency, and reduce the risk of product spoilage or damage. By leveraging real-time temperature data and analytics, businesses can proactively address potential issues, ensure product quality, and maintain customer satisfaction.

Sustainable Packaging Solutions

As the world becomes increasingly focused on sustainability, the cold chain industry is wholeheartedly embracing the exploration and development of eco-friendly packaging solutions. With a strong dedication to reducing our environmental footprint, these sustainable alternatives aim to tackle the unique challenges of temperature-controlled transportation while minimizing waste and the use of resources. Now, let’s dive into some exciting advancements in this field that are worth highlighting:

a. Biodegradable and Compostable Materials

When it comes to sustainable packaging, a crucial strategy is the utilization of biodegradable and compostable materials. These materials are sourced from renewable resources and possess the remarkable ability to break down naturally into harmless components, lessening our impact on the environment. Biopolymers like polylactic acid (PLA) and cellulose-based materials are garnering widespread recognition for their biodegradability and suitability for temperature-sensitive products. Embracing these eco-friendly alternatives not only reduces waste but also paves the way for a greener and more responsible approach to packaging.

b.Recyclable Packaging

Another aspect of sustainable packaging is the incorporation of recyclable materials. Packaging solutions that can be easily recycled help minimize waste generation and conserve valuable resources. Cold chain companies are increasingly adopting packaging made from recyclable plastics, paper-based materials, and cardboard, enabling more efficient recycling processes and reducing the overall carbon footprint.

c.Insulation with Renewable Materials

To improve insulation properties while considering sustainability, there is a growing focus on utilizing renewable and environmentally friendly materials. Natural fibers, such as hemp, jute, or cotton, are being explored as insulation components to replace traditional synthetic materials. These renewable alternatives offer effective thermal protection and can be composted or recycled at the end of their life cycle, promoting a circular economy.

d.Reusable Packaging

In recent years, reusable packaging solutions have captured considerable interest and acclaim. By developing packaging systems that can be utilized multiple times, the cold chain industry strives to minimize waste and decrease dependence on disposable materials. Reusable containers, pallets, and insulation components not only foster sustainability but also yield long-term cost savings. This approach aligns with our commitment to a greener future while offering practical benefits for businesses in the cold chain sector.

e.Energy-efficient Cooling Systems

In addition to sustainable packaging materials, energy-efficient cooling systems play a crucial role in promoting eco-friendly practices. Incorporating advanced refrigeration technologies, such as energy-efficient compressors, evaporative cooling, and intelligent temperature control systems, allows for optimized energy consumption during transportation. By implementing these systems, we can achieve superior temperature management while minimizing the environmental impact associated with excessive energy use.

Embracing sustainable packaging solutions in the cold chain industry brings forth a multitude of benefits. Beyond reducing carbon emissions and waste generation, it elevates brand reputation, meets consumer expectations, and aligns with regulatory requirements. By placing sustainability at the forefront, companies can contribute to a greener future and foster a more resilient and responsible cold chain ecosystem. Together, we can make a meaningful difference in shaping a sustainable and thriving world.

Why it is Important to use the Latest Temperature-Controlled Packaging

To safeguard the integrity and effectiveness of these sensitive products, the use of the latest temperature-controlled packaging has emerged as an essential requirement.

Preserving Product Quality and Efficacy

One of the primary reasons why using the latest temperature-controlled packaging is so important lies in its ability to preserve product quality and efficacy. Many goods, such as vaccines and medications, are highly sensitive to temperature fluctuations. Deviations from the recommended temperature range can render them ineffective, reducing their therapeutic value or even posing risks to patient safety. By using cutting-edge packaging technology, we can create an environment that shields these products from extreme temperatures, maintaining their potency and quality.

Mitigating Financial Losses

Temperature excursions during transit can lead to substantial financial losses for businesses. Perishable food items, for instance, can spoil if exposed to unfavorable temperatures, resulting in wasted inventory and lost revenue. Similarly, pharmaceutical companies may face significant financial setbacks if their products are compromised due to inadequate temperature control. By adopting the latest temperature-controlled packaging solutions, businesses can mitigate these losses by ensuring that their products remain within the required temperature range, protecting their investments and reputation.

Meeting Regulatory Compliance

Numerous industries, particularly those dealing with healthcare and food, are subject to stringent regulatory guidelines. These regulations mandate the maintenance of specific temperature conditions during storage and transportation to guarantee product safety and effectiveness. Falling short of these requirements can lead to severe consequences, such as legal penalties, product recalls, or damage to a company’s reputation. Staying up-to-date with the latest temperature-controlled packaging technologies allows businesses to meet and exceed these regulatory standards, ensuring compliance and avoiding any potential setbacks.

Enhancing Supply Chain Efficiency

Efficiency is a fundamental aspect of any supply chain, and temperature-controlled packaging serves as a critical driver in optimizing this process. By embracing the latest packaging solutions, companies can reap a host of advantages, including enhanced temperature control, decreased product spoilage, and extended shelf life. These factors collectively contribute to a more streamlined supply chain, with fewer disruptions caused by damaged goods, reduced waste, and improved inventory management. As a result, customer satisfaction is heightened, profitability is bolstered, and a competitive edge is gained in the market. Prioritizing efficient temperature-controlled packaging is a strategic move that brings both operational and commercial benefits, positioning businesses for long-term success.

Embracing Sustainable Practices

In recent years, sustainability has emerged as a top priority across diverse industries. The latest advancements in temperature-controlled packaging reflect this growing focus, as they incorporate eco-friendly materials and innovative design features aimed at reducing environmental impact. These solutions prioritize the use of recyclable or biodegradable packaging materials, optimize insulation to minimize energy consumption, and explore reusable packaging alternatives. By wholeheartedly embracing these sustainable practices, businesses not only safeguard their products but also play an active role in shaping a greener and more sustainable future for all.

Click here to find out more about Cold Chain Packing & Logistics today.