Digitalisation is defined as ‘the transformation of processes and methods to improve productivity, efficiency, and reliability using digital technology.’ When carried out gradually, digitalisation can lead to a massive transformation in any business. Among the many components of today’s business operations, supply chain can also be enhanced with digitalisation. Following the COVID-19 pandemic, many global supply chain networks were crippled and they were unable to cope with the rapidly changing situations and some supply chain processes still revolved around paper-based and face-to-face transactions. As most countries implemented lockdowns and physical distancing measures, it became more and more difficult to carry out supply chain processes.

In fact, most enterprises have only about 20% visibility into their supply chains, as opposed to the 70% to 90% needed to address key points of volatility where revenue and costs are at risk. (1) The proper implementation of digitalisation makes it easier, more reliable, and more efficient to bring products and services from the development to customer service stages.

With that in mind, we are going to take a look at some of the reasons why supply chain digitalisation is important for businesses in a post-COVID world:

Compliance- regulations are becoming more restrictive to ensure that manufacturers and service providers comply with pandemic mitigation regulations. For pharmaceutical products with short shelf lives and services that require more direct interactions with clients, the digitalisation of the supply chain will help businesses in ensuring that all processes remain compliant. In global trades, governments regulate transactions between buyers and sellers. Digitalisation will minimise obstructions and anticipate possible issues in the supply chain due to COVID-related changes. This means, documentations, orders, material sourcing, production, inventory, deliveries, and payments will all be handled digitally.

Efficiency- in a post-COVID business environment, more processes become paperless. With digitalisation, there will be no more manual inputs using less sophisticated processes. With scanners, new entries of information can be inputted directly into the digital system using QR codes or barcodes. Digitalisation avoids labour-intensive tasks and errors can be traced and verified better. A good digitalisation system is cross-platform, which supports any hardware and software implementation that suppliers, government agencies, and buyers currently use.

Better Accuracy- data accuracy is the direct result of supply chain digitalisation. Computer systems can convert, read, and interpret digital documents very accurately with no errors between processes. During manual processes, it is easy to miss a few details that can hamper shipment or delivery processes. Following the completion of transactions, the digitalisation of supply chain can help the management team track risks of fraud, procurement trends, and cash flow. Information from digitalised supply chain can be used by business owners to make informed decisions and mitigate risks in the market.

Cold Chain Packing & Logistics Digitalisation Solutions

As a result of the COVID pandemic, Cold Chain Packing & Logistics has invested heavily in digitalisation which enables us to offer our clients added value through analytical business intelligence.

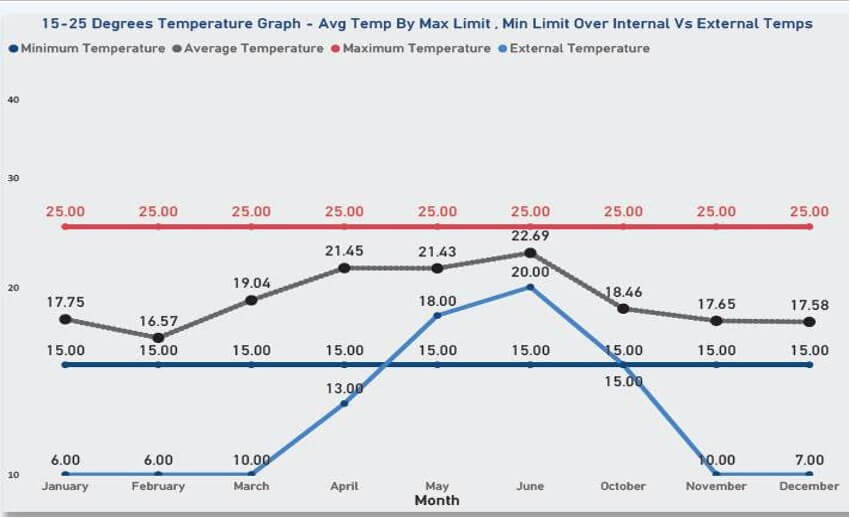

They can now analyse our success rate within the global supply chain lanes, by either the performance of our passive packaging by reviewing internal temperature vs external temperatures, or based on type of packaging selected or any particular lane.

As you can see by the following images, we analyse the annual average temperature and performance of packaging using IoT by integrating our live tracking devices in the entire supply chain process. This gives us better access to forecast the correct packaging type and solution for any particular lane or supplier. This initiative also provides financial analytics and statistical data on number of shipments/weight/lanes we need for forecasting and budgeting processes.

Contact Cold Chain Packing & Logistics

Cold Chain Packing & Logistics’ custom tailored solutions are designed to comply with the World Health Organization’s good distribution practices (GDP) regulations as well as Saudi FDA guidelines. To learn more, contact Cold Chain Packing & Logistics today and speak with a Pharma Logistics distribution expert who can answer any questions you might have.

If you enjoyed this article, please feel free to share it on your favourite social media sites.

[1] Information courtesy of Supply Chain Brain- https://www.supplychainbrain.com/blogs/1-think-tank/post/31062-in-2020-supply-chain-digitization-is-no-longer-optional