Discover what is Cold Chain Regulations and Compliance. Explore the essential rules and standards governing the temperature-controlled transportation and storage of goods.

It’s critical to maintain temperature while shipping internationally. For commodities that require a certain temperature to be maintained throughout lengthy transportation, the cold chain is essential. It is similar to a series of well-planned procedures that guarantee perishable goods remain secure, excellent, and fresh.

Effective cold chain management is crucial. It ensures that commodities arrive at their destination undamaged and secure. In this article will go into great detail about What is Cold Chain Regulations and Compliance.

What is cold chain, and what features does it have?

Let us first define what a “cold chain” is. Fresh fruit, perishable foods, and medications are examples of goods that must be properly stored and delivered according to a “cold chain” system. Ensuring the safety, efficacy, and quality of these commodities throughout their entire path from manufacturing to distribution is made possible by this method. The cold chain has the following essential components:

Uninterrupted transportation: Using a continuous network to convey items is one of the cold chain’s distinctive features. This suggests that from the distribution point to the customer’s door, the items must be kept at a consistent and controlled temperature throughout the whole production process.

Continuous observation: To make sure that temperatures stay where they should be, we need to keep a tight eye on the cold chain. We use tools like thermometers, hygrometers, data recorders, and other temperature indicators for this. The quality and safety of the items might be jeopardized if the temperature rises over the allowed limits. As a result, we must keep checking in often and take swift action as needed.

Control of temperature: Keeping the right temperature is important when handling food. We use fancy tools like data loggers and sensors to make sure the surroundings are just right for moving and storing food. These gadgets help us catch any temperature changes early on and prevent any harm to the products.

For food safety: It’s a big deal in the food industry. We need to store meals in places where we can control the temperature to make sure people get healthy and safe food. This helps avoid any contamination and stops harmful microorganisms from growing.

The efficacy of medications: In the pharmaceutical industry, quality control of pharmaceuticals is essential. This is particularly true for medications whose effects are influenced by temperature. Medication, vaccinations, and biotech goods may not function properly if they get too cold. For this reason, temperature control and monitoring are extremely strictly enforced in the pharmaceutical business.

Control and observation of the cold chain: A wide range of individuals, including salesmen, manufacturers, shippers, and transportation coordinators, are involved in the intricate process of managing the cold chain. We must keep a careful eye out for any issues and take prompt action to fix them in order to guarantee the security of our possessions.

Some essential components of cold chain management are as follows:

Careful planning: is necessary to guarantee that everything proceeds according to schedule and that the temperature doesn’t change while the products are being transferred.

Smart Technology: We use advanced sensors and monitoring systems to get temperature measurements from our gadgets in real time. This facilitates our capacity to render educated decisions.

Instruction and Training: A high degree of knowledge is required of the cold chain managers. They thus receive training to aid in their understanding of the importance of the protocol and the rules.

Tailored Solutions: Since every business is different, we need to create cold chain management plans that are suitable for the specific goods we are transporting.

Putting It All Together: Coordination and efficiency are required at every stage of the process, from manufacture to distribution to the merchants. This way, we can deal with any circumstance efficiently.

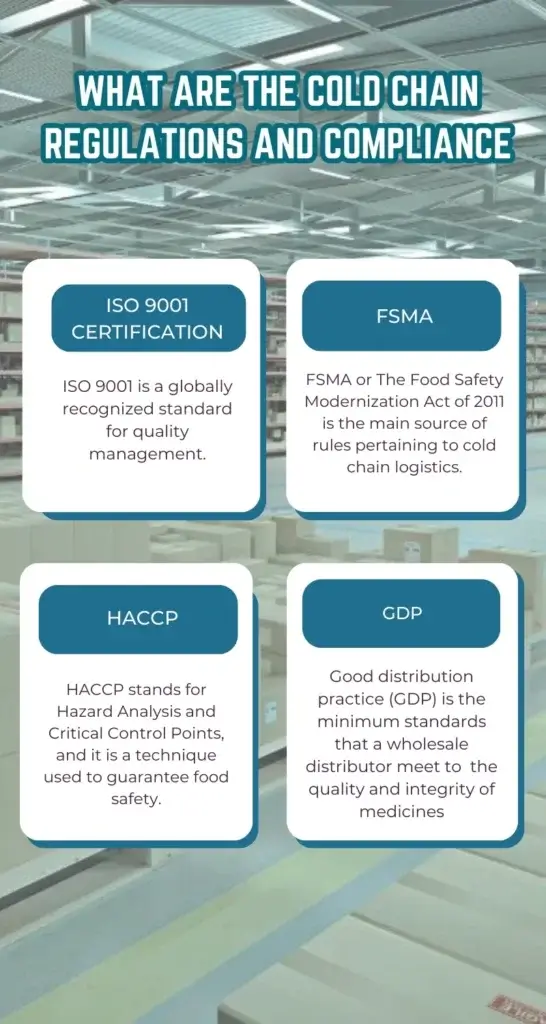

What Are Cold Chain Regulations and Compliance

The preservation of cold conditions during transportation is essential to guaranteeing the quality and safety of goods that need certain temperatures. Cold chain laws are intended to protect public health, preserve pharmaceutical efficacy, and guarantee that food preserves all of its nutrients and flavors. Let’s take a closer look at these rules.

Food safety standards: HACCP

HACCP stands for Hazard Analysis and Critical Control Points, and it is a technique used to guarantee food safety. This is the way food is prepared and handled in Europe. It was included to the German Food Hygiene Ordinance in 1998. A key element of this concept is identifying hazards and vital places where attention is required to maintain food safety.

For instance, maintaining a consistent temperature is crucial while moving and chilling food. We should regularly check the temperatures stated on food packaging, per HACCP. Additionally, there must to be a minimum and maximum temperature. To demonstrate that we are constantly keeping the food cold, we are required by HACCP to maintain a record of every temperature we measure.

The manufacturer or the guidelines determine the proper temperature when we move food. The food’s manufacturer indicates the ideal temperature if it’s ready to consume. However, the law requires us to maintain certain temperatures for raw materials. For example, chicken should never exceed +4 degrees Celsius, and minced meat should never exceed +2 degrees Celsius.

Food Safety Modernization Act of 2011

The Food Safety Modernization Act of 2011 is the main source of rules pertaining to cold chain logistics. The statute greatly increased the Food and Drug Administration’s control over how products are handled and transported from the manufacturer to the merchant to the final customer. The portion of the act that deals with the hygienic transportation of food intended for human or animal use contains many of the cold chain requirements that this act covers. The Sanitary Transportation Rule specifically addresses:

Equipment cleanliness and functionality: This section requires routine audits of equipment, particularly refrigeration equipment, to make sure it is in working order and can maintain the proper temperature. It also specifies how trucks, pallets, and other equipment must be cleaned in between loading in order to reduce the possibility of cross-contamination.

Transportation protocols: The protocols section covers rules pertaining to product handling during transportation, such as the need for workers to wear gloves or to periodically check the temperature of goods on separate pallets. It also deals with timeliness; in order to ensure the security of goods that are sensitive to temperature, cars must arrive at their destination within a suitable amount of time.

Training: In order to preserve the integrity of the cold chain, workers must get training on the safe and correct handling of food. For the purpose of certifying these persons, the FDA offers a free training program; however, supply chain managers are free to create their own. The training program can satisfy this criteria as long as employees understand their role in protecting food integrity, can spot possible problems with food safety, and can explain how to address them.

Records: The aforementioned clauses all call for a paper trail. Records of how staff members are educated to adhere to these rules, how food pallets are handled, and how their equipment is maintained must be kept by managers.

Pharmaceutical Regulation

The requirements known as “cool chain” are quite strict when it comes to the pharmaceutical business. When exposed to temperatures above or below the recommended ranges, medications—especially those that are temperature-sensitive—may become less effective. Regulatory bodies have devised comprehensive protocols for the distribution, storage, and transportation of pharmaceuticals, with special focus on the preservation of consistent temperatures during the whole procedure.

Quality certifications

Many firms seek globally recognized certifications in order to guarantee the best quality of product and verify compliance with cold chain standards. Among the most well-known is the ISO 9001 certification, which confirms compliance with strict quality control guidelines. Furthermore, the pharmaceutical sector has its own certifications, such GDP (Good Distribution Practice).

Data monitoring and recording

Cold chain laws frequently call for careful observation and documentation of product temperature data throughout storage and transit. This information may be utilized to spot any problems down the chain and as proof that laws are being followed. Utilizing sophisticated monitoring tools, such data loggers and sensors, has grown in popularity as a means of guaranteeing data integrity and traceability.

Conclusion

In conclusion, businesses can only guarantee the integrity of their products by using efficient cold chain management. The cold chain is becoming more dependable and effective due to the ongoing development of technology and management techniques, particularly for exports outside of the country. Are you trying to find a trustworthy delivery company for your perishable goods? Make contact with Logistics & Cold Chain Packing.