We will delve deeper into the topic of IoT in Cold Chain Logistics in this post, including its definition, how it helps manage the cold chain, and its risks.

Internet of Things Cold Chain Logistics: What Is It? It’s revolutionary for companies to rely on keeping products at certain temperatures. Executives in the logistics and pharmaceutical sectors are reevaluating their management approaches in the wake of the major disruptions to supply chains caused by COVID-19.

Perishable commodities, such as food and medication, must be maintained at the proper temperature at all times along the supply chain, and this is your responsibility as a business. A temperature overflow might lead to waste, spoiling, and even safety risks.

IoT Cold Chain Monitoring is useful in this situation. The application of some amazing new technologies will determine process reliability, safety, and efficiency. We are discussing artificial intelligence, the Internet of Things (IoT), and big data analytics.

Envision a system of linked gadgets and sensors that monitors the temperature of your goods while they are being delivered. You receive up-to-date information whenever the temperature fluctuates. This aids in identifying any problems before they worsen.

What is the Internet of Things?

The term “Internet of Things” refers to a system of interconnected devices that provide a continuous flow of data to individuals and/or other devices over the internet, influencing decision-making in real time. For instance, with consumer IoT, you might use a smartphone app to manage the temperature in your home.

The Internet of Things is a network of interconnected things (devices, appliances, goods) and people. It might be tiny, including one person and one item, or massive, involving thousands of devices and people. A person who has access to this data through an app, website, or secure data sharing platform can monitor anything from location to internal and external temperature and check to see if something was opened, compromised, or even stolen when a “thing” is equipped with a sensor or other similar device that can send specific data types either live or at predetermined intervals.

With the help of the Internet of Things, businesses can streamline labor-intensive, often cumbersome manual processes out of their production and supply chains. This results in continuous data streams that can inform people about the state of their supply chains and help make quick, automated decisions.

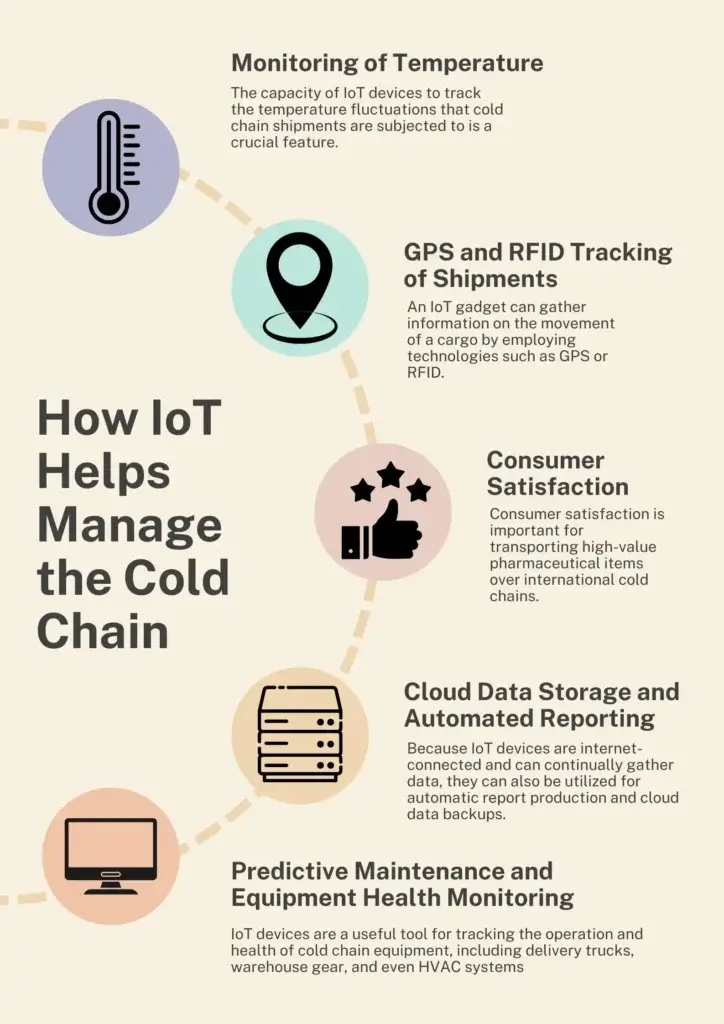

How IoT Helps Manage the Cold Chain

Here are some examples of how companies are already utilizing IoT to improve cold chain logistics.

1. Monitoring of Temperature

The capacity of IoT devices to track the temperature fluctuations that cold chain shipments are subjected to is a crucial feature.

Sensors can be used in a variety of transportation modes, such as trucks, rail freight, or air cargo, to continuously track the temperature of food items, critical pharmaceuticals, and other items that require cold chain logistics. This can be done by attaching an Internet of Things temperature monitor to the outer layer of a package or pallet.

Real-time data collection and reporting will be done by these sensors. All pertinent parties can obtain the temperature data that IoT sensors gather as they can automatically save data on the cloud.

If an IoT sensor detects a temperature anomaly, an alert system may instantly notify managers, drivers, administrative staff, and other personnel, allowing them to take appropriate action to avoid spoiling.

Data may also be utilized to optimize operations, detect bottlenecks, and pinpoint blame if an error causes spoiling. Stakeholders may evaluate collected information and trends at any time after a sensor gathers temperature data — or utilize analytics tools to automatically extract significant insights from past temperature data.

IoT temperature tracking systems may also monitor other characteristics of a shipment’s travel, such as exposure to light, shocks, vibrations, and unexpected pauses.

Many cold chain items require more than just low temperatures. Many vaccinations, for example, that need cold chain logistics may deteriorate or lose efficacy if exposed to light. Sudden shocks can also cause vaccination containers and packing materials to be damaged.

IoT devices that monitor temperature can also aid in the detection of these possible risks.

2. GPS and RFID Tracking of Shipments

IoT devices are also great for tracking the present position of a cargo or a single product. An IoT gadget can gather information on the movement of a cargo by employing technologies such as GPS or RFID.

This information will be available in real time thanks to GPS. The RFID system will rely on RFID readers positioned in strategic locations to continually scan for RFID tags. When an RFID-tagged shipment arrives at a warehouse, fulfillment center, retail outlet, or delivery destination, these systems will give quick updates.

These systems may automatically notify stakeholders when an item is in motion, allowing them to trace the whereabouts of all their shipments 24 hours a day, seven days a week. Temperature and location may both be monitored by the same IoT device.

The same technology can also assist businesses and logistics providers in providing more accurate delivery predictions to their customers. It is considerably easier to predict when an item will arrive at a location with real-time tracking.

3. Consumer Satisfaction

Consumer satisfaction is important for transporting high-value pharmaceutical items over international cold chains, but it is not the same as cold chain security. Is your payload in jeopardy? Is the payload tainted? The ability to continuously track vital parameters, such as onboard and exterior temperatures, when and where the package was opened, and who opened it, are critical questions that IoT enables us to answer.

Knowing that your customer’s cargo is safe and effective is a valuable asset when offering your cold chain services to potential or current partners. The Internet of Things also offers answers to questions that were previously unanswerable. The annual cost of spoiled pharmaceutical cargo is estimated to be $35 billion.

4. Cloud Data Storage and Automated Reporting

Because IoT devices are internet-connected and can continually gather data, they can also be utilized for automatic report production and cloud data backups.

For example, data from an IoT device can be stored for future periodic recording of important information or provided right away to important stakeholders.

An Internet of Things device has the potential to send data not only to the cloud but also to logistics management systems, where dashboards and other data visualization tools allow stakeholders to review the data.

The device may also transmit data to analysis tools driven by AI, enabling businesses to use IoT data to power algorithms for temperature or delivery time forecasts.

These algorithms can help businesses foresee a disaster based on patterns in IoT data, sometimes even before a manager or analyst would see the issue independently.

5. Predictive Maintenance and Monitoring of Health Equipment

In addition to being able to directly monitor shipments, IoT devices can be used to track the performance and condition of cold chain equipment, such as delivery trucks, warehouse equipment, and even HVAC systems.

Many types of environmental and performance data can be tracked by the IoT performance monitoring devices that are now in place. Businesses can monitor machine health and performance with the use of these systems’ data.

For instance, information regarding a machine’s timing, vibration, temperature, and lubrication may be gathered by an IoT fleet. Should any of these variables surpass its permitted range of operation, the system might automatically alert site technicians.

IoT sensors may also assess local temperature, humidity, and CO2 levels, allowing warehouse or fulfillment center managers to determine whether local environmental conditions are affecting the functioning of a site equipment.

Because equipment monitoring is already a popular use of IoT devices in many sectors, cold chain logistics experts interested in adopting the technology have access to a wide and expanding market of IoT equipment monitoring solutions.

Experts believe that the industry will expand rapidly over the next several years, providing logistics organizations with even more alternatives in the near future.

Businesses may also utilize IoT devices to establish the groundwork for a predictive maintenance system if they collect enough data. These are systems that estimate a machine’s maintenance needs using AI and IoT machine performance data.

It is possible to forecast when a machine will require maintenance or repairs by evaluating data obtained from IoT devices.

These systems may also notify management when they estimate that a machine will fail soon, allowing for an emergency shutdown that can assist to avert substantial damage to a machine, which could result in more expensive repairs and longer downtime.

What are the dangers?

As previously said, the primary goal of IoT has been to simplify processes while lowering costs and carbon emissions. Its potential to revolutionize all sectors in these ways is undeniable.

The nature of wireless communication, whether it’s your home wireless internet, your employer’s private staff intranet, or a worldwide IoT network, renders it vulnerable to security vulnerabilities. A key challenge for the widespread adoption of IoT in supply chain or cold chain logistics is avoiding data security threats, which could cost companies millions of dollars in fines or ransomware attacks that demand money in exchange for private data.

If we want to boost customer trust through live data supervision, we must also guarantee that this live data is encrypted, and that wirelessly linked devices like packaging, vehicles, or logistical hubs are developed with security not only in mind, but at the forefront of development.

IoT Solutions Could Be Required for Efficient Cold Chain Management

The rising importance of the cold chain has created a desire for innovative solutions that will assist businesses in better managing logistics. This is critical in today’s environment, when the demand for cold things is increasing and safety is paramount.

As the need for cold chain services grows, IoT technologies may become even more important. The correct equipment make it easier for managers to track cargo temperature and location, delivering quick warnings of any abnormalities.

This information may make it much simpler for cold chain managers to eliminate waste and loss, resulting in more effective logistical operations.