Two prominent names have emerged to redefine the way we safeguard and transport sensitive payloads: CoolGuard Advance and Crēdo Cube™. Today we will compare CoolGuard Advance to Credo.

In the ever-evolving world of temperature-controlled shipping, two names have emerged as frontrunners: CoolGuard Advance and Crēdo Cube™. As industries grapple with the challenge of transporting sensitive payloads, these innovations offer distinct approaches to safeguarding valuable products while also addressing the pressing need for sustainability. In this in-depth comparison, we delve into the features, benefits, and unique characteristics of each solution, shedding light on how they cater to different needs within the realm of cold chain logistics.

What is CoolGuard Advance

CoolGuard™ Advance represents a leap forward in the field of temperature-controlled shipping, backed by a fusion of phase change materials (PCM) and vacuum insulated panels (VIP). This powerful amalgamation ensures that each shipping container becomes a haven of temperature stability, extending the duration of protection to an impressive 72 to 120+ hours. This extended window of temperature stability is a critical feature for industries where maintaining the integrity of products, such as pharmaceuticals and biotechnological materials, is non-negotiable.

The heart of CoolGuard™ Advance lies in its high-performance VIP and PCM technology, a combination that not only reduces temperature excursions but also bolsters compliance with stringent regulatory guidelines. This leads to an optimally low total cost of ownership, as fewer excursions translate to minimized product loss and reduced risk of costly regulatory penalties. To learn more about CoolGuard Advance DOWNLOAD COOLGUARD ADVANCE DATASHEET

CoolGuard Advance : Features and Benefits

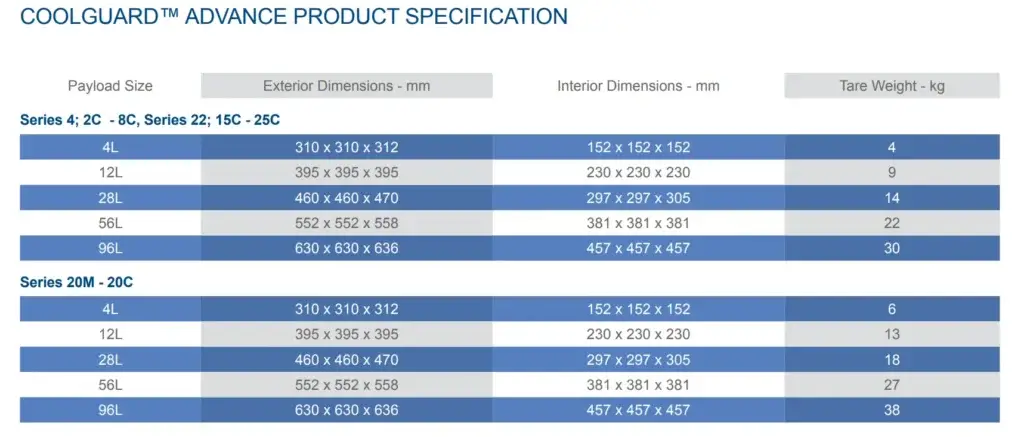

One of the standout features of CoolGuard™ Advance is its achievement of industry-leading payload to external volume ratios. This accomplishment not only maximizes storage space but also slashes distribution costs. With options such as 4L, 12L, 28L, 56L, and 96L payload sizes available, businesses gain the flexibility to choose the most suitable size for their specific shipping needs. This adaptability directly contributes to cost savings and environmental sustainability.

Another exceptional attribute is CoolGuard™ Advance’s hibernation capability, a feature that can be engaged at any point during transit. This functionality significantly extends the duration of temperature-compliant shipments, enabling the transport of valuable payloads across longer distances or during unexpected delays without compromising product quality.

Efficiency

CoolGuard™ Advance not only prioritizes the protection of payloads but also acknowledges the importance of streamlined logistics. The packing process is quick, simple, and practically error-free, thanks to its single-temperature approach and interchangeability of PCM coolants between CoolGuard™ Advance and CoolGuard™ PCM ranges. This interchangeability enhances efficiency and minimizes the risk of confusion during packing and dispatch.

With a range that spans from SERIES 4 (2°C to 8°C) to SERIES 22 (15°C to 25°C), CoolGuard™ Advance caters to diverse temperature requirements. Moreover, the different payload sizes further enhance its applicability across various industries.

What is Credo Cube

Crēdo Cube™ Peli BioThermal’s distinguishing feature lies in its capacity to ensure the integrity of medical materials within a precisely controlled temperature range for an extended period. This breakthrough technology not only guarantees the safety of crucial products but also aligns with global sustainability goals. By significantly reducing carbon footprint and wastage, Crēdo Cube™ actively demonstrates a commitment to responsible and eco-friendly shipping practices.

The Crēdo Cube™ series sets itself apart by offering a wide range of sizes and temperature ranges to cater to the diverse requirements of the life sciences industry. Ranging from 3 to 96 liter and providing consistent temperature control that lasts up to 5 days, these durable and lightweight packaging systems accommodate controlled room temperature, refrigerated, and deep-frozen conditions. This versatility ensures that organizations can make informed choices based on their specific shipping needs, reducing unnecessary costs and ensuring optimal product preservation. To learn more about Credo Cube DOWNLOAD CREDO CUBE DATASHEET

Crēdo Cube™ : Features

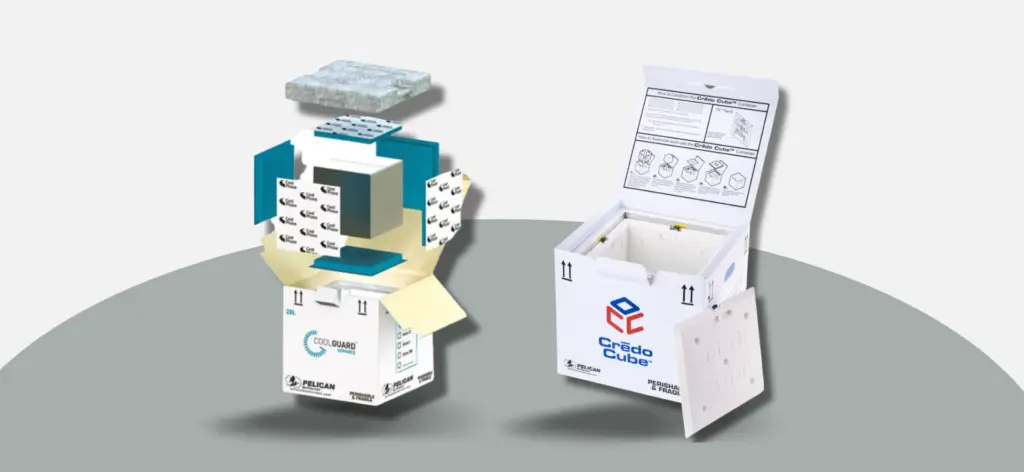

Crēdo Cube™ goes beyond its protective features; it incorporates a modular Thermal Isolation Chamber (TIC™) system that integrates PCM and VIPs. This intelligent design facilitates easy conditioning in a freezer for year-round shipping, streamlined packing processes, and efficient storage. The integration of the TIC™ walls with PCM guarantees stable performance by enclosing the payload securely.

Efficiency

Unforeseen delays during shipping can wreak havoc on sensitive payloads. Crēdo Cube™ is a robust solution designed to tackle such challenges head-on. Its construction employs high-performance Phase Change Material (PCM) for cooling and Vacuum Insulated Panels (VIPs) for top-notch insulation. This combination ensures that temperature-sensitive materials are safeguarded against external fluctuations, providing consistent temperature control that lasts up to 5 days.

Crēdo Cube™ shippers are put through their paces, being tested to ISTA7D profiles, ensuring their ability to withstand real-world shipping conditions. This rigorous testing underscores their reliability and performance, reinforcing their position as the most trusted and reliable high-performance reusable shippers available.

Monitoring and Cutting-Edge Software

In an era where data is paramount, Crēdo Cube™ offers Crēdo ProEnvision™ – an intuitive, web-based asset tracking software. This software provides secure, real-time tracking and monitoring to maximize investment returns. The optional TIC™ Smart Indicator, a temperature-sensitive label, offers a glanceable, safe temperature reading for added convenience and confidence.

Variants of Crēdo Cube™

1. CRĒDO CUBE™ SERIES 4

Designed to maintain temperatures between +2°C to +8°C, the Crēdo Cube™ SERIES 4 variant shines as a pinnacle of precision. With a remarkable duration of 96 to 168 hours, this variant provides ample time to ensure that temperature-sensitive materials remain at the exact temperature required for their safe transportation. The versatile payload sizes, ranging from 3L to 96L, allow organizations to select the optimal container size to match their shipment volume.

2. CRĒDO CUBE™ SERIES 22

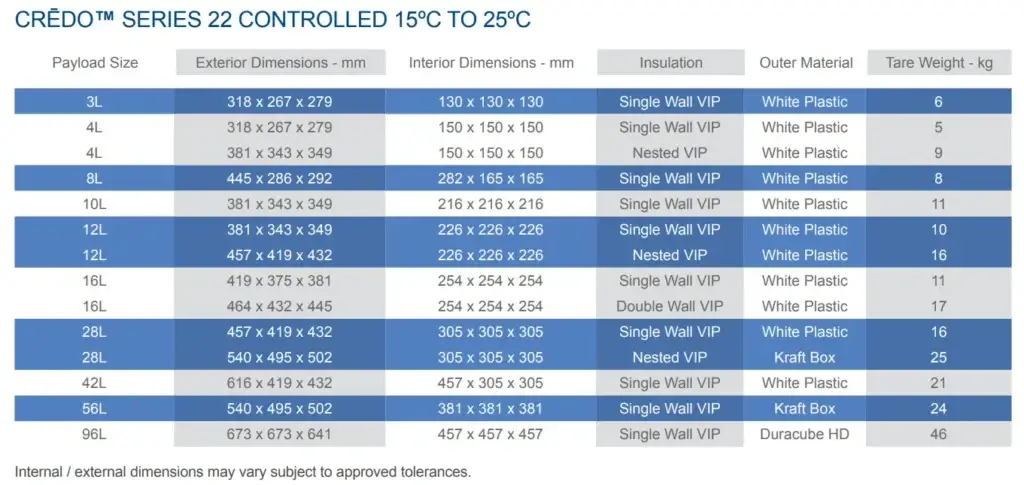

Within the SERIES 22 range, Crēdo Cube™ continues its legacy of precision, offering two distinct options:

SERIES 22 CONTROLLED: With temperatures spanning 15°C to 25°C and a duration of 96 to 168 hours, the Controlled Temperature variant is designed to maintain the stability of products that require specific temperature ranges. This variant is available in payload sizes from 3L to 96L, ensuring a fit for various shipping needs.

SERIES 22 UNIVERSAL: In situations demanding versatile temperature ranges, the Universal Temperature variant shines with the same duration and payload sizes as its counterpart. Offering temperatures between 15°C to 25°C, it provides flexibility without compromising on performance. Available in volumes of 9L, 24L, and 49L, it accommodates varying shipment sizes.

3. CRĒDO CUBE™ SERIES 20M, 50M & DRY ICE

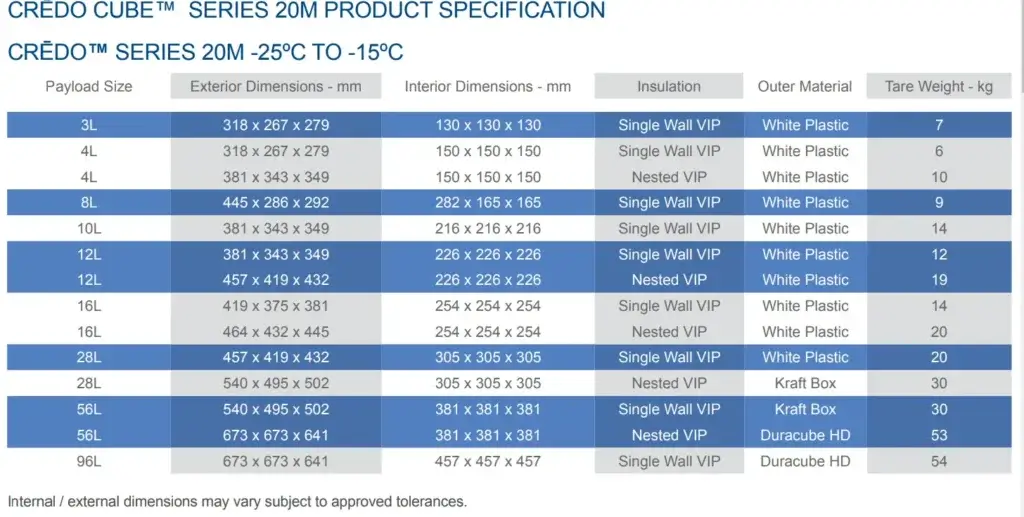

For scenarios that demand extreme temperature ranges, the CRĒDO CUBE™ SERIES 20M, 50M & DRY ICE variants step in:

SERIES 20M Variant: Built to withstand temperatures from -25°C to -15°C, the SERIES 20M variant maintains its performance over 96 to 168 hours. With payload sizes ranging from 3L to 96L, it covers a spectrum of shipping volumes and remains a reliable choice for cold chain logistics.

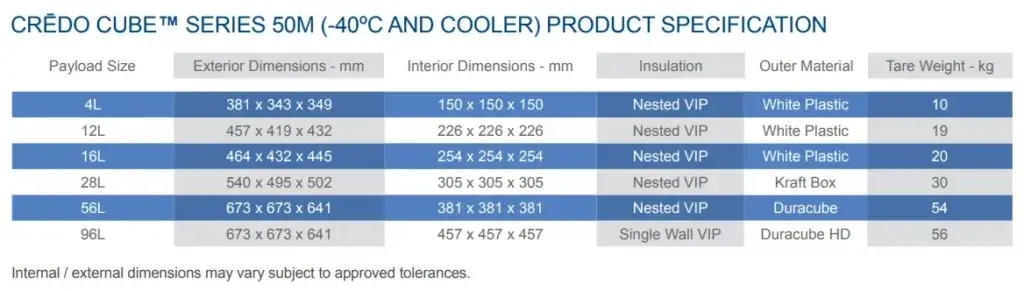

SERIES 50M Variant: Going even further, the SERIES 50M variant tackles temperatures below -40°C. With a duration of 96 to 168 hours and payload sizes spanning 4L to 96L, it’s engineered for the most demanding cold storage requirements.

CoolGuard Advance Compared to Credo

CoolGuard Advance and Crēdo Cube™ are built on the foundations of cutting-edge engineering, each incorporating unique technologies to achieve their goals. CoolGuard Advance’s focus on maintaining precise temperatures over an extended period positions it as the go-to solution for industries that demand exacting standards. On the other hand, Crēdo Cube™’s fusion of phase change materials and vacuum insulated panels emphasizes adaptability and sustainability, aligning with the evolving landscape of eco-friendly practices.

CoolGuard Advance introduces a paradigm shift in temperature-controlled shipping by fusing phase change materials (PCMs) and vacuum insulated panels (VIPs). The result is a highly efficient, single-use shipping system that guarantees extended temperature stability, lasting an impressive 72 to 120+ hours. This kind of resilience is crucial for industries where maintaining product integrity is paramount – think pharmaceuticals and biotechnological materials.

At the core of CoolGuard Advance is its VIP and PCM technology, which not only minimizes temperature excursions but also bolsters compliance with stringent regulatory standards

On the other hand, Crēdo Cube™ embraces a modular Thermal Isolation Chamber (TIC™) system that integrates PCM and VIPs. This unique design allows for easy conditioning in a freezer, simplifying the packing process and optimizing storage. The integration of the TIC™ walls with PCM guarantees secure and consistent temperature control, safeguarding the payload from external fluctuations.

Efficiency shines through with Crēdo Cube™, especially in tackling unforeseen shipping delays. The combination of high-performance Phase Change Material (PCM) for cooling and Vacuum Insulated Panels (VIPs) for insulation ensures that temperature-sensitive materials remain untouched by external variations. This level of consistency lasts up to five days, ensuring product integrity throughout the journey.

The CoolGuard Advance vs. Crēdo Cube: Sustainability

The environmental impact of shipping has never been more significant. CoolGuard Advance addresses the immediate need for protection, but it primarily centers on performance. In contrast, Crēdo Cube™ introduces a sustainable dimension that resonates with industries and consumers alike. By lowering cost and carbon footprints, Credo CubeTM presents itself as an advocate for environmentally friendly transportation methods. It’s not just about ensuring the quality of products; it’s about making a positive contribution to the environment.

The CoolGuard Advance vs. Crēdo Cube: Features and Benefits

CoolGuard Advance isn’t just about temperature stability; it’s about doing more with less. Its industry-leading payload to external volume ratios maximize storage space and significantly reduce distribution costs. The available payload sizes (4L, 12L, 28L, 56L, and 96L) provide flexibility for different shipping requirements, contributing to cost-effectiveness and environmental sustainability.

A remarkable attribute of CoolGuard Advance is its hibernation capability, allowing it to extend the duration of temperature-compliant shipments. This feature becomes particularly handy when valuable payloads need to travel longer distances or unexpected delays arise, without compromising product quality. . CoolGuard single use but give 5-6 days compared to Credo 3-4 days.

What sets Crēdo Cube™ apart is its extensive range of sizes and temperature options. Spanning from 3 to 96 liters. these lightweight packaging systems accommodate controlled room temperature, refrigeration, and deep freezing conditions, significantly reducing carbon footprint and wastage, Crēdo Cube™ actively demonstrates a commitment to responsible and eco-friendly shipping practices.

The CoolGuard Advance vs. Crēdo Cube: Versatility vs. Precision

In the end, an organization’s unique requirements will determine whether CoolGuard Advance or Crdo CubeTM is the better option. In circumstances when maintaining accurate temperatures for a prolonged period of time is crucial, CoolGuard Advance shines. Its high-performance protection and design are advantageous to industries working with delicate, temperature-sensitive items.

The Crdo CubeTM, on the other hand, excels in situations that call for adaptability and sustainability. It is the best option for companies looking to cut expenses while maintaining environmental responsibility because it can accommodate different temperature ranges and sizes. It fits perfectly with industries where unanticipated delays might be difficult because of its capacity to sustain temperatures for up to five days.

Conclusion

The unparalleled single-use shipping method provided by CoolGuard Advance stands out as a beacon of accuracy and offers more than just protection. Phase change materials (PCMs) and vacuum insulated panels (VIPs) combine to create CoolGuard Advance, which offers a longer temperature stability window of 5–6 days. When contrasted with the 3–4 days of stability provided by the Crdo CubeTM, this extraordinary characteristic becomes even more impressive. The CoolGuard Advance is a great option for businesses that need accuracy and endurance due to its industry-leading payload to external volume ratios and hibernation capacity.

On the other hand, Crēdo Cube™ steps into the spotlight with its dedication to sustainability and versatility. With a range of sizes and temperature options spanning 3 to 96 liters, Crēdo Cube™ accommodates diverse shipping requirements, reducing carbon footprint and waste along the way. This commitment to eco-friendly practices resonates deeply, aligning with the growing global movement toward responsible shipping solutions.

In the end, the option an organization chooses between CoolGuard Advance and Crdo CubeTM relies on its particular requirements. The 5- to 6-day stability and regulated assembly method of CoolGuard Advance offer a reliable option if keeping exact temperatures for a longer period of time is the top concern. Crdo CubeTM’s dedication to minimizing environmental effect while providing a variety of temperature settings makes it a clear winner for those looking for sustainability.