In the ever-evolving world of logistics, certain industries require specialised care and attention to ensure the safe and effective transport of their products. One such industry is pharmaceuticals and healthcare, where temperature-sensitive cargo demands precision, reliability, and expertise. This is where Cold Chain Logistics Thermal Solutions come into play.

Temperature monitoring is a crucial aspect of pharmaceutical management and a primary concern for pharmaceutic companies when choosing the proper logistics for their product. If pharmaceutical products do not maintain the appropriate temperature during transportation, this will result in products becoming ineffective and unsafe for consumption. For this reason, it is crucial to ensure that pharmaceutical products follow the rules and regulations put in place to ensure maximum efficiency and product integrity.

Proper storage and transportation of pharmaceutical products require strict temperature control to ensure their efficacy, potency, and safety. This can be done through a variety of cold chain methods such as data loggers, thermometers, and temperature-controlled packaging. With this in mind, the use of these cold chain methods does not ensure product integrity is maintained, each pharmaceutical product will have a specific set of requirements that need to be met and regulations that need to be adhered to.

Understanding Cold Chain Logistics Thermal Solutions

Cold Chain Logistics Thermal Solutions encompass a set of strategies and technologies aimed at maintaining a specified temperature range throughout the transportation and storage of temperature-sensitive goods. These solutions are critical for industries where product efficacy and safety depend on precise temperature control, such as pharmaceuticals, biotechnology, and healthcare.

Why is Temperature Monitoring Important?

Pharmaceutical products, such as vaccines, drugs, and temperature-sensitive goods, are sensitive to temperature variations. Deviations from the recommended temperature range can lead to a loss of potency, degradation of active ingredients, and even potential harm to patients. Temperature fluctuations can occur during storage, transportation, and handling, making it essential to monitor and maintain optimal conditions throughout the supply chain.

Key Components of Cold Chain Logistics Thermal Solutions

- Temperature-Controlled Packaging: One of the fundamental aspects of Cold Chain Logistics is the use of specialised packaging materials designed to insulate and protect sensitive cargo from temperature fluctuations. This includes thermal blankets, insulated containers, and refrigerated packaging solutions.

- Monitoring and Data Logging: Real-time monitoring and data logging systems are employed to track the temperature conditions of cargo during transit. This technology allows for immediate intervention if temperature deviations occur, ensuring cargo integrity.

- Temperature-Controlled Vehicles: Transportation vehicles such as refrigerated trucks and containers are equipped to maintain the desired temperature throughout the journey. These vehicles are crucial for long-distance transportation of sensitive cargo.

- Cold Storage Facilities: Cold Chain Logistics often involves the use of temperature-controlled storage facilities. These warehouses maintain the required temperature range for extended periods, ensuring the integrity of stored goods.

- Regulatory Compliance: Compliance with industry regulations and guidelines, such as Good Distribution Practices (GDP) and Good Manufacturing Practices (GMP), is essential to ensure the quality and safety of pharmaceutical and healthcare products during transportation and storage.

The Importance of Cold Chain Logistics Thermal Solutions

- Product Integrity: Cold Chain Logistics Thermal Solutions are vital for preserving the efficacy and safety of temperature-sensitive products, such as vaccines, blood samples, and medications. Maintaining the correct temperature range is essential to prevent product spoilage and maintain their therapeutic properties.

- Patient Safety: In healthcare, patient safety is paramount. Cold Chain Logistics ensures that medical products and supplies, like organs for transplantation or blood products, remain safe for use.

- Regulatory Compliance: Strict adherence to regulatory standards is not only a legal requirement but also a way to uphold the reputation of pharmaceutical and healthcare companies. Cold Chain Logistics Thermal Solutions help in meeting these standards.

Challenges in Temperature Monitoring

Temperature monitoring in the pharmaceutical industry presents several challenges. One of the primary challenges is maintaining the cold chain during transportation. Pharmaceuticals often need to be transported over long distances, and any lapse in temperature control can have significant consequences. Factors such as extreme weather conditions, power outages, or human error can disrupt the cold chain and compromise the integrity of the products.

Another challenge is the need for real-time monitoring and alerting systems. Traditional temperature monitoring methods, such as manual temperature checks, are time-consuming and prone to human error. Furthermore, relying solely on periodic checks can lead to delayed detection of temperature excursions, increasing the risk of product spoilage. A robust temperature monitoring system should provide continuous monitoring and instant notifications to enable timely interventions.

Methods for Temperature Monitoring

Data Loggers: Data loggers are portable electronic devices that record and store temperature data over time. They are commonly used for monitoring temperature during transportation. Data loggers are equipped with sensors that measure and record temperature at regular intervals. Once the shipment reaches its destination, the data can be downloaded and analysed to assess the integrity of the pharmaceutical products during transit.

Thermometers and Temperature Labels: Traditional thermometers and temperature-sensitive labels are often used for manual temperature checks. While they are cost-effective, they require frequent monitoring and may not provide real-time data. Temperature-sensitive labels change colour when exposed to specific temperature ranges, allowing for a quick visual inspection of temperature deviations.

Wireless Monitoring Systems: Wireless temperature monitoring systems offer real-time data collection and remote access. These systems consist of wireless sensors placed in storage areas or transportation containers, which transmit temperature data to a centralised monitoring system. This allows for continuous monitoring and immediate alerts in case of temperature excursions, ensuring timely corrective actions.

Thermal Mapping: Thermal mapping involves the use of temperature sensors to map the temperature distribution within storage areas, such as warehouses or cold rooms. By analysing the data collected from multiple sensors, it is possible to identify temperature variations and potential hotspots. Thermal mapping helps optimise the storage layout and ensure uniform temperature distribution, minimising the risk of product damage.

Cold Chain Packaging: Cold chain packaging includes insulated containers, gel packs, and temperature-controlled packaging solutions. These packaging materials help maintain the required temperature range during transportation. Some advanced solutions even incorporate temperature monitoring sensors directly into the packaging, providing an additional layer of protection and visibility.

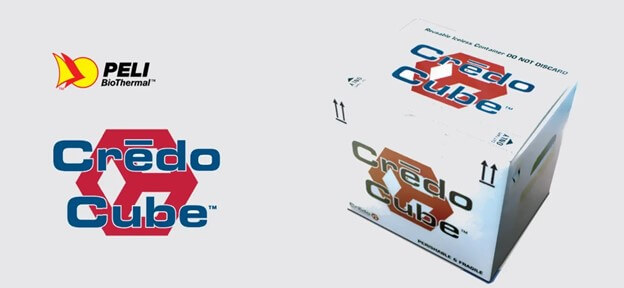

Crēdo Cube: In the fast-paced world of shipping and cold chain logistics, innovation takes centre stage with solutions that not only ensure product safety but also resonate with environmental responsibility. The Crēdo Cube, a flagship product from Peli BioThermal, stands as a testament to this ethos. This cutting-edge container is engineered to provide a highly efficient and sustainable solution for maintaining temperature-sensitive cargo during transit. With advanced insulation and temperature-control technology, the Crēdo Cube™ ensures that pharmaceuticals, medical supplies, and other critical cargo remain impeccably preserved throughout their journey. To explore the features, benefits, and revolutionary impact of the Crēdo Cube™ on temperature-controlled shipping, we invite you to dive deeper into our comprehensive guide, available at this link.

Find out more about our Cold Chain Logistics, Elpro Monitoring Solutions, Thermal Mapping services.

Our Cold Chain Consultancy service takes the needs of your business into consideration when considering Middle East logistics. Whether you are a manufacturer seeking to identify or mitigate risks in any of the Critical Control Points in your distribution chain, or a logistics provider looking to serve the healthcare sector through GDP compliance, Cold Chain Packing & Logistics will work with your team to develop cost-effective end-to-end solutions for your needs. We consider the complexities of each stage of logistics and distribution and can best advise on all elements of your supply chain to ensure we can meet your strategic objectives.

If you’re interested in finding out more about Cold Chain Logistics or need more information on how we can help your cold chain shipping, contact us at coldchainpacking.com today!