Article’s Summary

- Pharma Logistics – a dynamic field that encompasses the intricate dance of transporting, storing, and distributing drugs and medical supplies with precision and care.

- Maintaining precise temperature control and vigilant monitoring holds paramount importance, especially when dealing with temperature-sensitive products like vaccines, biologics, and certain medications

- Pharmaceutical companies and logistics providers need to invest in robust documentation and record-keeping practices.

- Secure packaging helps prevent damage from physical impacts and provides a barrier against moisture, light, and other environmental factors that could degrade the product’s quality.

In the grand symphony of healthcare, there’s a vital rhythm that hums through every note, synchronizing the delivery of life-saving medications and pharmaceutical products to the hands of those who need them most. This behind-the-scenes maestro is none other than Pharma Logistics – a dynamic field that encompasses the intricate dance of transporting, storing, and distributing drugs and medical supplies with precision and care.

Beyond the cold algorithms of technology, Pharma Logistics is a realm that brims with human stories and dedication. It’s a harmonious blend of innovation and empathy, where professionals work tirelessly to ensure that medications reach patients’ bedsides at the right time and in optimal condition. While the logistical complexity can be daunting, the collective mission to improve global healthcare unites practitioners and stakeholders worldwide.

In this article, we’ll embark on a human-centric journey to explore the realm of Pharma Logistics and uncover 5 Tips for Pharma Logistics. Beyond the cold mechanics, these tips are grounded in compassion and the unwavering desire to provide the best possible care to patients worldwide. So, let’s join hands and embark on this journey to uncover the secrets of successful Pharma Logistics.

5 Tips for Pharma Logistics

1. Temperature control and monitoring

In the world of healthcare logistics, maintaining precise temperature control and vigilant monitoring holds paramount importance, especially when dealing with temperature-sensitive products like vaccines, biologics, and certain medications. Failing to uphold the required temperature range during transportation and storage can result in compromised potency, reduced effectiveness, and, in severe cases, harmful side effects when administered to patients.

To guarantee stringent temperature control, pharmaceutical companies and logistics providers rely on specialized packaging, such as insulated containers and refrigerated trucks. For items that are particularly sensitive to temperature variations, a meticulous cold chain management system becomes indispensable. This involves meticulously maintaining a controlled temperature environment throughout various stages, encompassing production, storage, transportation, and distribution.

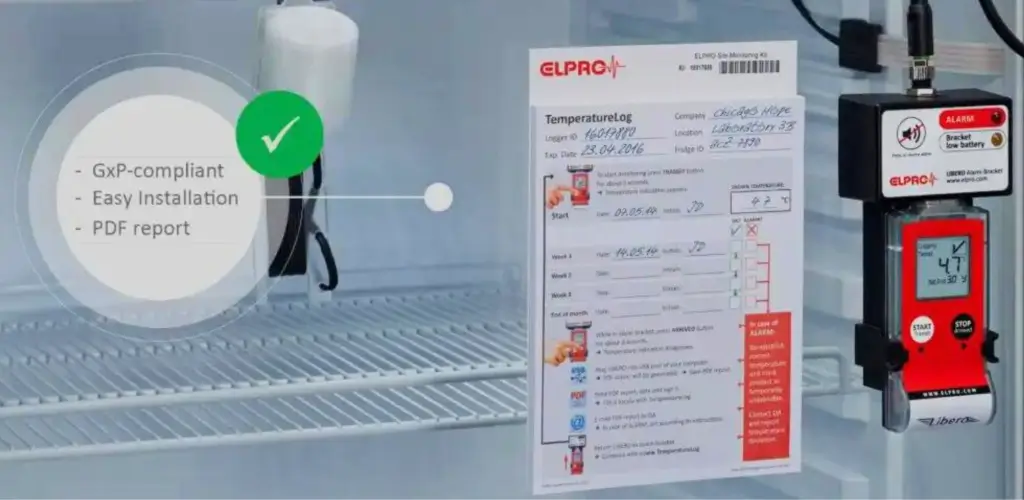

To ensure the integrity of these temperature-sensitive products, pharmaceutical companies make significant investments in sophisticated temperature monitoring systems. These state-of-the-art systems are equipped with temperature loggers, data loggers, or IoT-enabled sensors, enabling the continuous collection of real-time temperature data. With this vigilant monitoring in place, any deviations from the prescribed temperature range prompt immediate action, thereby reducing the risk of product spoilage and preserving their therapeutic efficacy.

Nonetheless, it’s not just technology that plays a pivotal role in safeguarding these vital pharmaceutical products. Human expertise and meticulous training of personnel involved in the logistics process are equally indispensable. These dedicated professionals are well-versed in the specific temperature requirements of each product and adhere to best practices for their proper storage and transportation.

For example, let’s consider the transportation of vaccines, which are highly sensitive to temperature variations. A pharmaceutical company developing a new vaccine needs to maintain the vaccine’s efficacy during transportation from the manufacturing facility to medical clinics worldwide. They utilize insulated containers to protect the vaccines from external temperature fluctuations.

To monitor the vaccines’ temperature conditions during transit, the company installs temperature loggers inside the containers. These loggers continuously record the temperature, transmitting real-time data to a centralized system using IoT technology. This system allows the company’s logistics team to track the vaccines’ temperature status at any given moment.

Moreover, the logistics team undergoes specialized training to handle the vaccines properly. They understand the specific temperature requirements for the vaccine and the critical importance of maintaining the cold chain. They carefully load and unload the containers to minimize exposure to external environments that could impact the vaccines’ stability.

In the case of any temperature excursions, the real-time monitoring system triggers alerts, prompting the logistics team to take immediate action. They can adjust the temperature settings, reroute shipments if necessary, or arrange for a backup cold storage facility to ensure the vaccines remain within the specified temperature range.

2. Compliance with regulations

The pharmaceutical industry is heavily regulated to ensure patient safety and product quality. Compliance with various guidelines and regulations is essential for pharmaceutical logistics. Key regulations that impact pharmaceutical logistics include Good Distribution Practices (GDP), Good Manufacturing Practices (GMP), and various regional and international standards.

GDP outlines the guidelines for the proper distribution of medicinal products, including storage, transportation, and documentation. Compliance with GDP ensures that pharmaceutical products are handled in a manner that maintains their quality and prevents counterfeiting.

On one hand, GMP (Good Manufacturing Practice) is all about the manufacturing side of pharmaceuticals. It’s all about making sure that products are made and managed consistently, adhering to strict quality standards. However, it also affects logistics, as proper handling and transportation are essential for maintaining the integrity of products during distribution.

Pharmaceutical companies and logistics providers need to invest in robust documentation and record-keeping practices. These records should include details about the transportation process, temperature data, handling procedures, and any deviations from the standard protocols. Detailed records are vital for regulatory audits and for identifying any potential issues in the supply chain.

To comply with regulations, pharmaceutical companies often perform risk assessments and implement risk mitigation strategies. This process involves identifying potential risks in the supply chain and taking measures to minimize their impact. Regular audits and inspections are conducted to ensure adherence to established standards.

3. Secure packaging and labeling

Proper packaging and labeling are essential to protect pharmaceutical products during transportation and storage. Secure packaging helps prevent damage from physical impacts and provides a barrier against moisture, light, and other environmental factors that could degrade the product’s quality.

Pharmaceutical packaging must also be tamper-evident, meaning any attempts to tamper with the package are immediately visible. Tamper-evident seals and labels give assurance to patients and healthcare providers that the product is safe and has not been compromised.

In addition to secure packaging, clear and accurate labeling is critical. Each package should include essential information such as the product name, batch number, expiration date, storage instructions, and handling precautions. Proper labeling ensures that products are easily identifiable, and their usage is safe and efficient.

Pharmaceutical labeling must also comply with relevant regulations and standards, including those related to product identification, dosage, and usage instructions. Language translations may be necessary for products distributed internationally.

Advanced packaging technologies, such as temperature-indicating labels, RFID tags, and smart labels, can enhance visibility and transparency in the supply chain. These technologies allow real-time tracking of the product’s condition and location, enabling immediate action in case of deviations or delays.

4. Efficient inventory management

Inventory management is a cornerstone of successful pharmaceutical operations, ensuring that essential medical products are readily available when needed, while minimizing wastage and avoiding frustrating stockouts. A well-executed inventory management strategy begins with a comprehensive demand forecasting process, which relies on a mix of historical data, market trends, and other pertinent factors. This forecasting enables pharmaceutical companies to anticipate the demand for their products accurately and prepare accordingly.

To facilitate this intricate process, pharmaceutical companies turn to specialized software systems designed to monitor inventory levels, track expiration dates, and implement efficient stock rotation practices. By doing so, they can strike the right balance in their inventory, guaranteeing that items nearing their expiration dates are dispatched or used first, a practice known as the “first in, first out” (FIFO) approach. This approach minimizes the risk of products expiring before they can be utilized, safeguarding against unnecessary waste.

Moreover, for temperature-sensitive pharmaceuticals, it is imperative to adopt an additional strategy called “first-expired, first-out” (FEFO). The FEFO approach prioritizes products that are closest to their expiration dates, ensuring that those with limited shelf life are utilized before their efficacy declines. This careful consideration protects the value of valuable medicines and maintains the high standard of care expected in the pharmaceutical industry.

To validate the accuracy of recorded stock levels and ensure accountability, regular cycle counts and physical inventory audits are routinely conducted. These practices provide a hands-on means of identifying any discrepancies or potential losses in the inventory. By taking a proactive stance on inventory accuracy, companies can minimize errors and maintain smooth operations.

Yet, the true essence of efficient inventory management extends beyond in-house practices. Collaboration and open communication with Pharma Logistics company, suppliers, manufacturers, and distributors play a pivotal role in streamlining the supply chain. By sharing demand forecasts and real-time inventory data, all stakeholders can work harmoniously, ensuring products are produced, transported, and delivered in sync with market needs. This collaborative effort enhances responsiveness and helps avert any potential disruptions, fostering an environment of trust and mutual understanding.

Additionally, pharmaceutical companies might explore the benefits of “just-in-time” (JIT) inventory management strategies. The JIT approach aims to minimize storage costs and reduce the risk of product obsolescence by maintaining lean inventory levels. However, it’s crucial to approach JIT with caution, considering the critical nature of pharmaceutical products. Striking the right balance between minimizing inventory costs and maintaining an adequate buffer to meet unforeseen demand fluctuations is essential to avoid compromising patient care.

5. Partner with reliable Pharma logistics providers

Selecting the right logistics partners plays a vital role in the pharmaceutical industry, ensuring the secure and efficient transportation of products. One of Pharma logistics examples is ColdChainpacking.com

Pharmaceutical companies must exercise meticulous due diligence before entering into partnerships with logistics providers. This entails evaluating the provider’s experience in handling pharmaceuticals, inspecting their facilities and infrastructure, and verifying their compliance with regulations.

It is crucial to opt for logistics providers that possess temperature-controlled facilities and transportation capabilities, particularly if the products require cold chain management. Having well-maintained refrigerated trucks and warehouses equipped with monitoring systems is essential.

The training of logistics employees is another pivotal factor to consider. Pharmaceutical companies should ensure that the staff is appropriately trained to handle temperature-sensitive items and hazardous materials.

Establishing transparent communication channels with logistics partners is imperative for addressing concerns promptly. Conducting regular performance reviews and feedback sessions fosters continuous improvement and strengthens the partnership

Why pharma freight forwarding is important

Pharma freight forwarding is incredibly important in the pharmaceutical industry because it plays a vital role in ensuring that life-saving medications and sensitive medical products reach their intended destinations safely and on time.

When it comes to pharmaceuticals, there’s no room for mistakes or delays. These products often have strict temperature requirements, especially those that fall under the cold chain category. Without proper handling and transportation, the efficacy and safety of these medications could be compromised, putting patients’ health at risk.

Pharmaceutical companies, therefore, need reliable logistics partners who specialize in handling these sensitive shipments. Pharma freight forwarding companies have the expertise and infrastructure to provide temperature-controlled transportation, ensuring that the products maintain their integrity throughout the entire journey.

By choosing the right logistics partner, pharmaceutical companies can rest assured that their products are in capable hands. These logistics providers understand the regulations and requirements of the industry, and they have the necessary certifications to handle pharmaceuticals properly.

Moreover, pharma freight forwarding companies often have advanced monitoring systems in place, allowing real-time tracking of shipments. This level of visibility is crucial in identifying any potential issues or deviations from the required conditions so that immediate action can be taken.

In conclusion, it’s clear that pharmaceutical logistics is a highly complex and crucial aspect of the healthcare industry. The well-being of countless patients relies on the seamless transportation of life-saving medications and medical supplies.

To achieve this, the five tips we’ve discussed—ensuring temperature control and monitoring, complying with stringent regulations, secure packaging and labeling, efficient inventory management, and partnering with trusted pharma freight forwarding companies—serve as the pillars of a successful and efficient pharmaceutical supply chain.

By prioritizing these strategies, pharmaceutical companies can rest assured that their products will maintain their integrity throughout the entire journey. From the manufacturing facility to the hands of patients, these careful logistics measures contribute to improved patient care and better public health outcomes.

Ultimately, the impact of efficient pharmaceutical logistics goes far beyond just delivering packages—it can mean the difference between life and death for patients around the globe. And by continually refining and improving these logistics practices, we can work together to enhance the well-being of people worldwide and bring positive change to the healthcare landscape.